The design principle of the

aluminum bronze casting process is mainly based on the physical and chemical properties, composition and required final product properties of the aluminum bronze alloy. The following is a detailed explanation of the design principles of the aluminum bronze casting process:

Alloy composition and properties

Aluminum bronze alloy is mainly composed of aluminum, copper and other alloying elements (such as iron, manganese, nickel, etc.). The content and proportion of these elements have a significant impact on the properties of the alloy. For example, in ZCuAl10Fe3 alloy, the aluminum content is relatively high, reaching 9.5% to 11.0%, and it also contains an appropriate amount of iron element, which can significantly improve the strength, hardness and wear resistance of the alloy.

Smelting and pouring

smelting

Smelting is a process of melting raw materials at high temperatures. By controlling the heating temperature and time, the raw materials are completely melted and mixed thoroughly. During the smelting process, appropriate amounts of flux and slag remover need to be added to improve the melting effect and reduce the impurity content. For aluminum bronze alloys, the control of melting temperature is crucial. Too high or too low a temperature may cause quality problems in the alloy.

pouring

Pouring is the process of pouring molten alloy into a mold. Before pouring, the mold needs to be preheated to increase the temperature of the mold and reduce heat loss. In order to prevent defects such as pores and slag inclusions during the pouring process, the molten alloy needs to be degassed and filtered. The design of the pouring system and the control of the pouring speed are also key factors affecting the quality of castings.

Cooling and solidification

After pouring is complete, the casting gradually cools and solidifies. Controlling the cooling rate and time is crucial to ensure the performance of the casting. The faster the cooling rate, the finer the grains of the casting and the better the mechanical properties. However, too fast cooling rate may cause defects such as cracks in castings. Therefore, a reasonable cooling process needs to be formulated based on the structural and dimensional requirements of the casting.

Casting methods and mold design

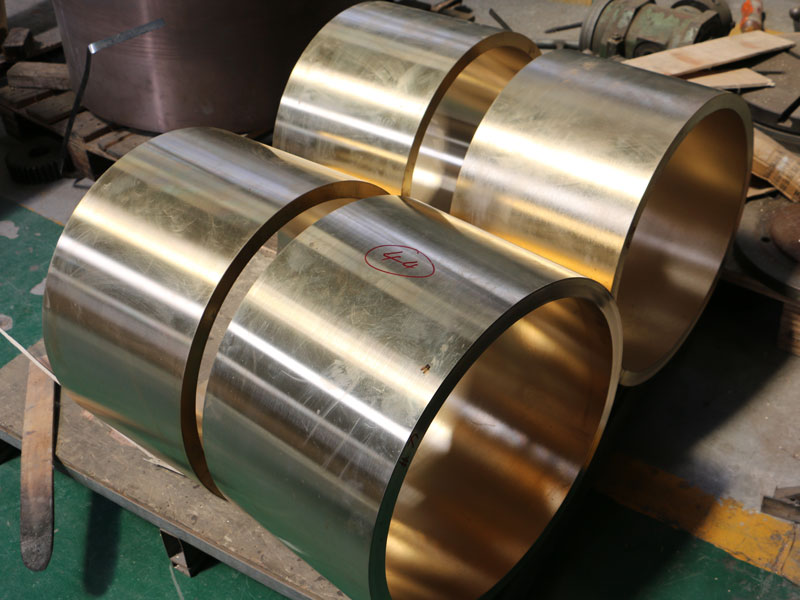

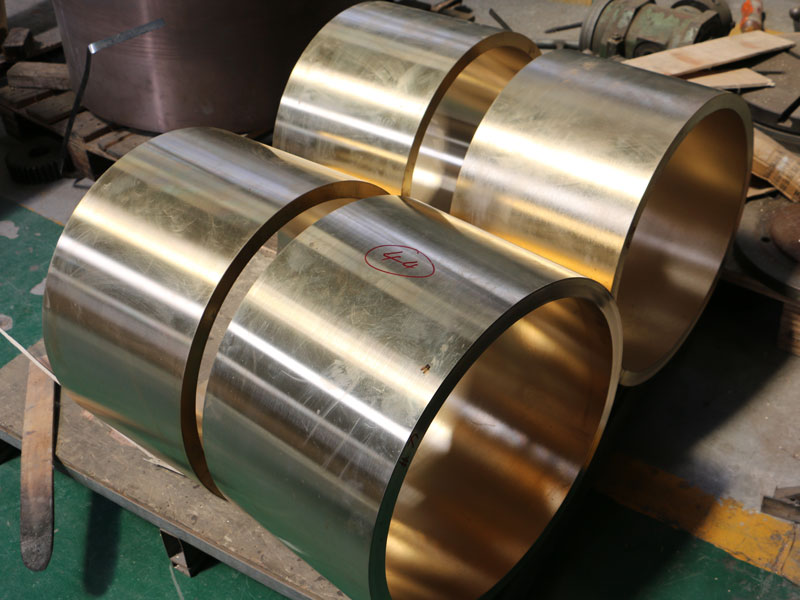

Commonly used casting methods for aluminum bronze include continuous casting, die casting and sand casting. Different casting methods are suitable for different production needs and casting shapes. Casting mold design requires designing a reasonable mold structure based on the structural and dimensional requirements of the casting, and using high-temperature resistant materials to make the mold. During the casting design process, factors such as the strength, stiffness and sealing of the mold need to be considered to ensure the quality and accuracy of the casting.

Quality control and performance testing

In order to ensure that the quality and performance of aluminum bronze casting alloys meet the requirements, a series of quality control and performance testing are required. This includes quality control of raw materials, monitoring of the smelting process, control of the pouring process, and post-processing (such as cleaning, processing, etc.) and performance testing (such as mechanical property testing, corrosion resistance testing, etc.) of castings.

Summarize

The design principles of the aluminum bronze casting process involve alloy composition and properties, smelting and pouring, cooling and solidification, casting methods and mold design, quality control and performance testing, etc. Through precise process control and alloy ratio, aluminum bronze materials with excellent mechanical properties and corrosion resistance can be produced to meet the needs of various industrial fields.