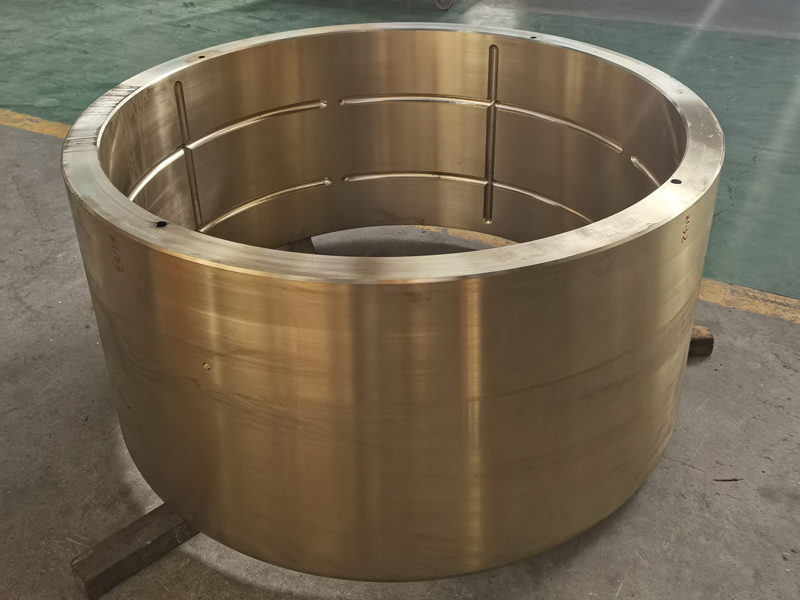

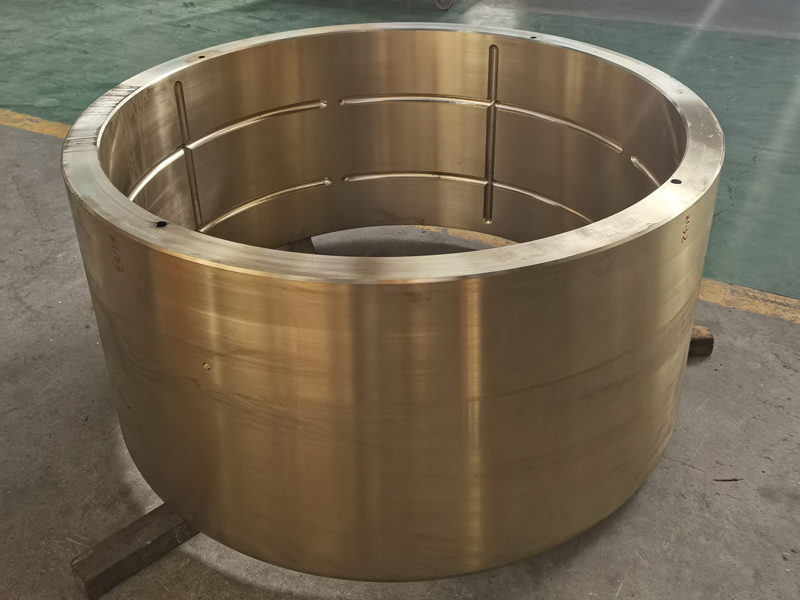

Process principle of centrifugal casting of copper alloys:

The centrifugal casting method of

copper alloys is a special casting process. Its principle is to pour liquid metal into a rotating mold, so that the liquid metal fills the mold and solidifies under the action of centrifugal force. This method is mainly used for castings of special shapes such as rings, tubes, cylinders, and sleeves.

The characteristics of centrifugal casting of copper alloys include:

1. The molten metal fills and solidifies under the action of centrifugal force, and the metal shrinkage compensation effect is good: the outer layer of the casting is dense, with few non-metallic inclusions and good mechanical properties.

2. Save material and equipment investment: No molding or core making is required, saving related materials and equipment investment.

3. Improve metal utilization: Casting hollow castings does not require pouring and risers, and the metal utilization rate can be greatly improved.

Therefore, for certain specific shapes of castings, centrifugal casting is a material-saving, energy-saving, and high-efficiency process.