The difficulties in the production and casting of large

bronze parts are mainly reflected in the following aspects:

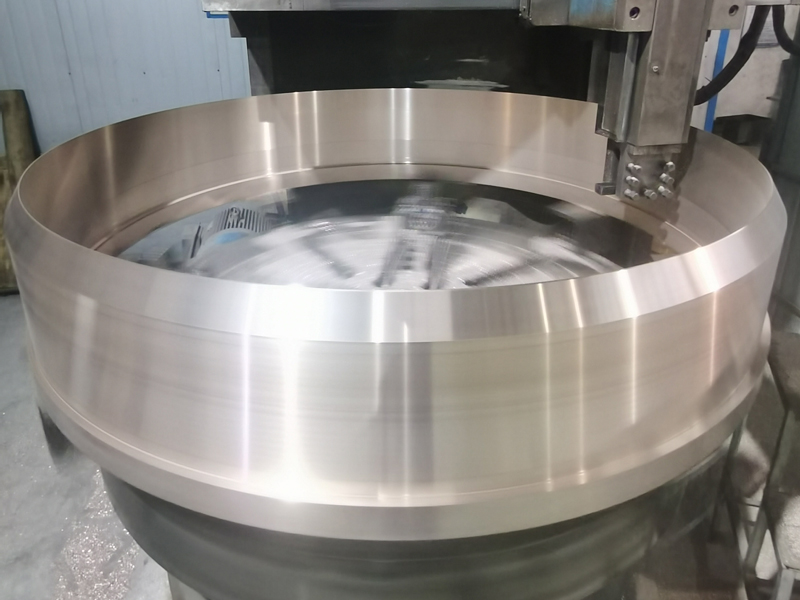

Casting quality control

Defects such as pores, inclusions, shrinkage holes and cracks may appear inside the casting, seriously affecting the performance. It is necessary to optimize the casting process, improve the performance of the molding sand and improve the smelting quality to prevent them.

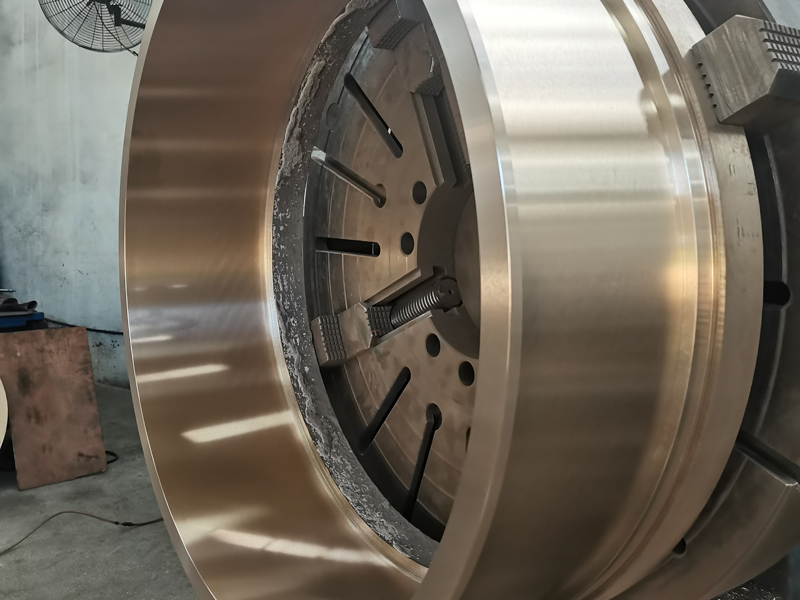

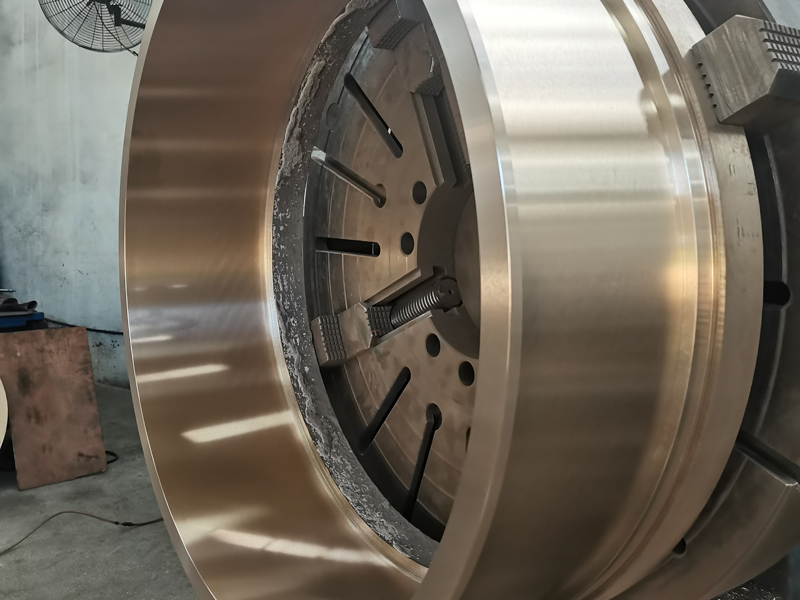

Mold design and material selection

Improper mold design or material defects may cause various problems in the casting. The quality of raw materials must be strictly controlled, and the mold design must be carefully managed.

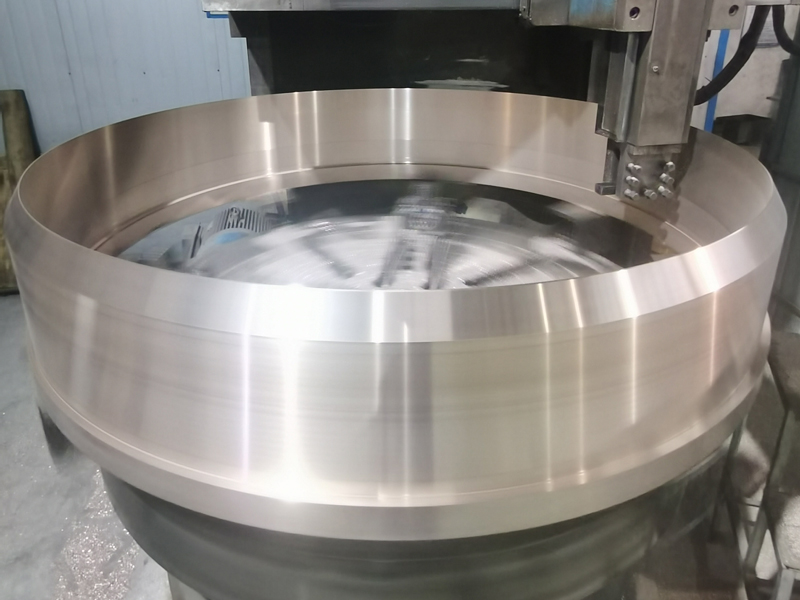

Casting environment and process stability

Fluctuations in environmental factors such as temperature and humidity and process instability may affect the quality of castings. The stability of the processing process must be maintained.

Energy consumption and environmental pollution

The foundry industry has high energy consumption and serious environmental pollution. It is necessary to work on the greening and sustainability of the production process.

Talent shortage

There is a serious shortage of casting technical talents, which affects technological innovation and quality control.