When choosing the right

bronze bushing to optimize equipment efficiency, the following aspects can be considered:

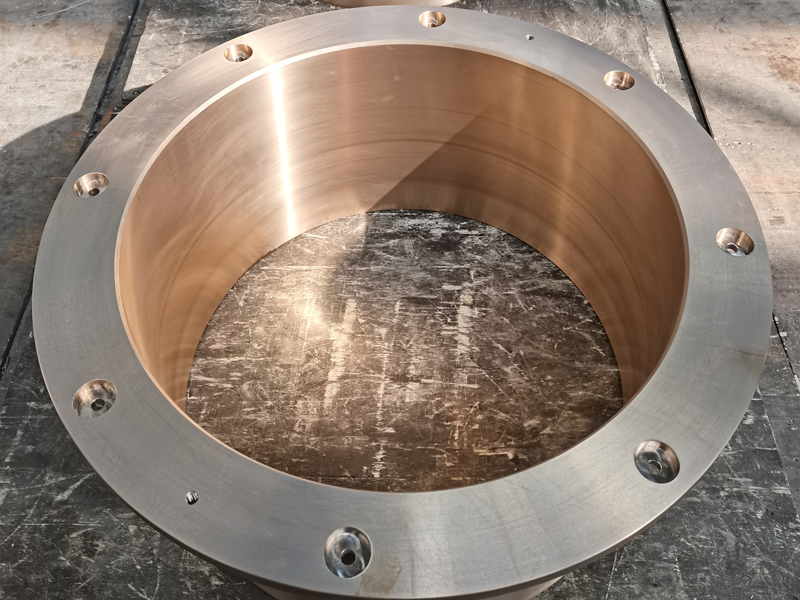

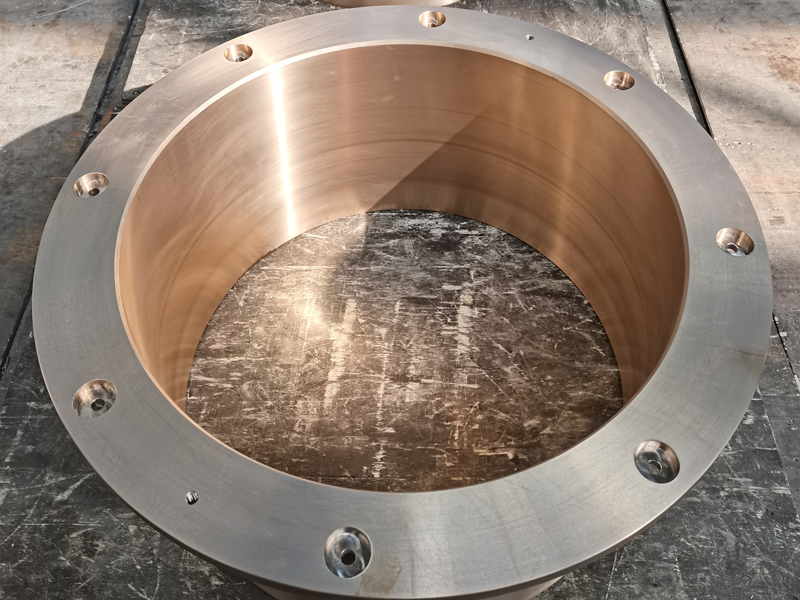

Material Selection

Given that different types of bronze (such as aluminum bronze, phosphor bronze, etc.) each have unique mechanical properties, corrosion resistance, and wear resistance, it is necessary to select the right material according to the working environment and load requirements of the equipment.

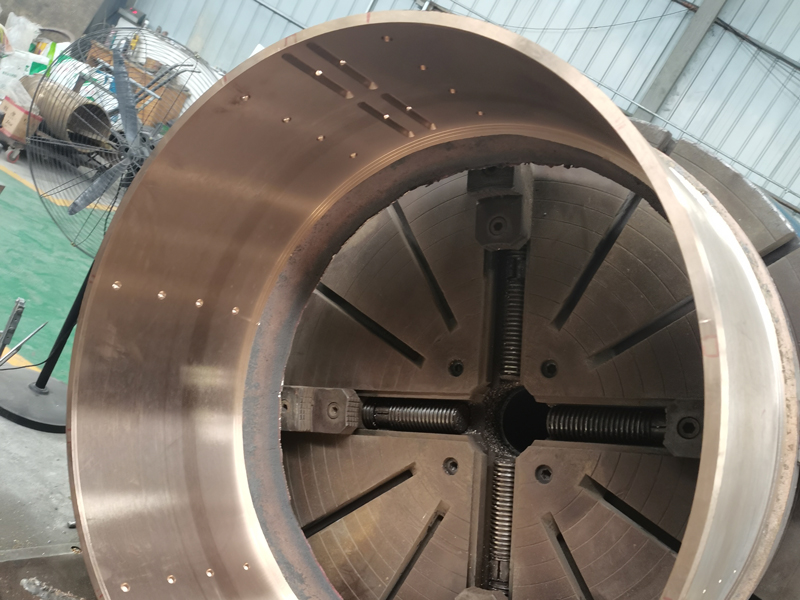

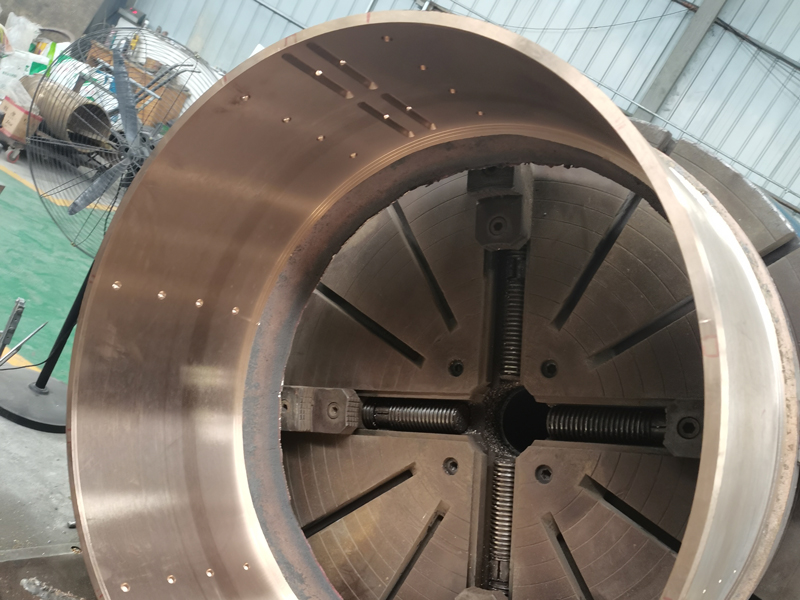

Dimensions and Tolerances

It is necessary to ensure that the dimensions and tolerances of the bronze bushing strictly meet the requirements of the equipment to prevent wear and poor operation due to dimensional problems. To this end, strict inspections should be carried out using precise measuring tools.

Lubrication Method

It is necessary to consider the lubrication method of the bronze bushing (such as oil lubrication or dry lubrication) and select a suitable lubricant to reduce friction and wear, thereby improving equipment efficiency.

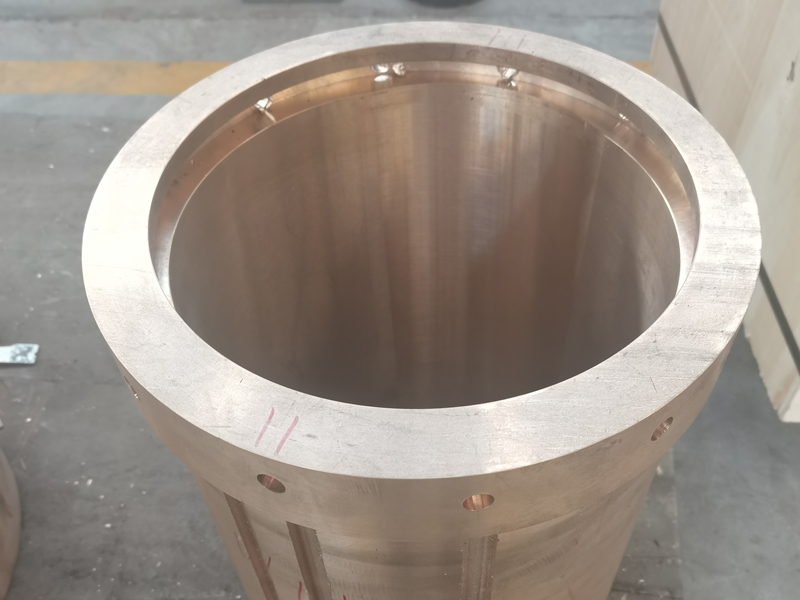

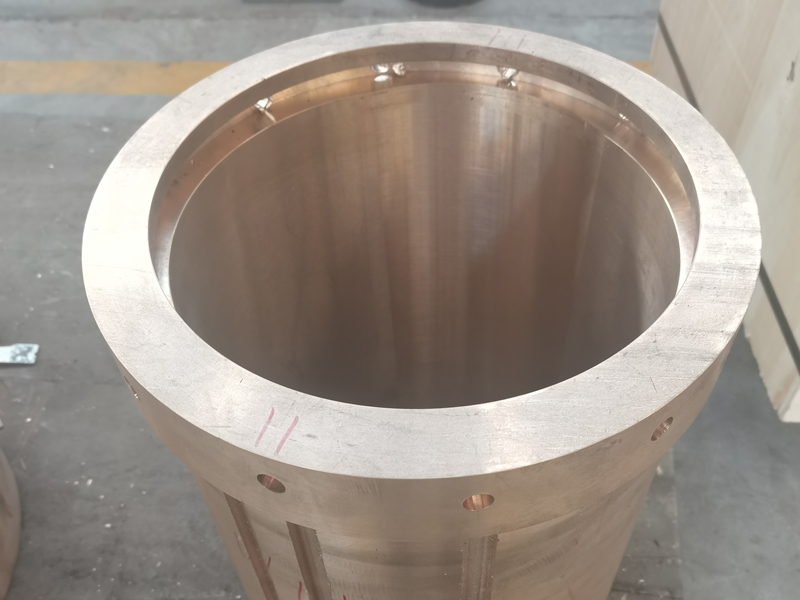

Heat Treatment Process

Proper heat treatment can enhance the hardness and strength of the bronze bushing. Therefore, choosing a heat-treated bronze bushing material will help improve its wear resistance and service life.

Applicability to application conditions

When selecting a bronze bushing, it is also necessary to fully consider the equipment's operating temperature, load, speed and environmental conditions to ensure that the selected bronze bushing can work stably and reliably under these conditions.

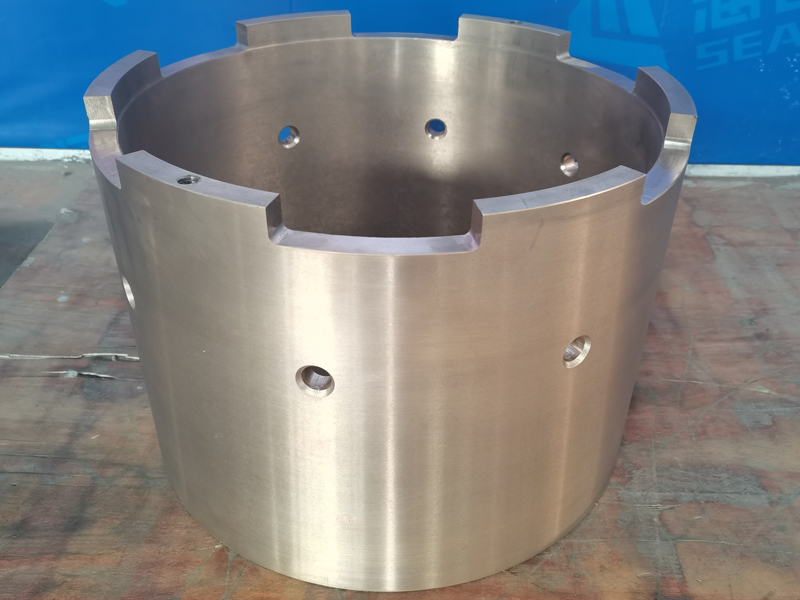

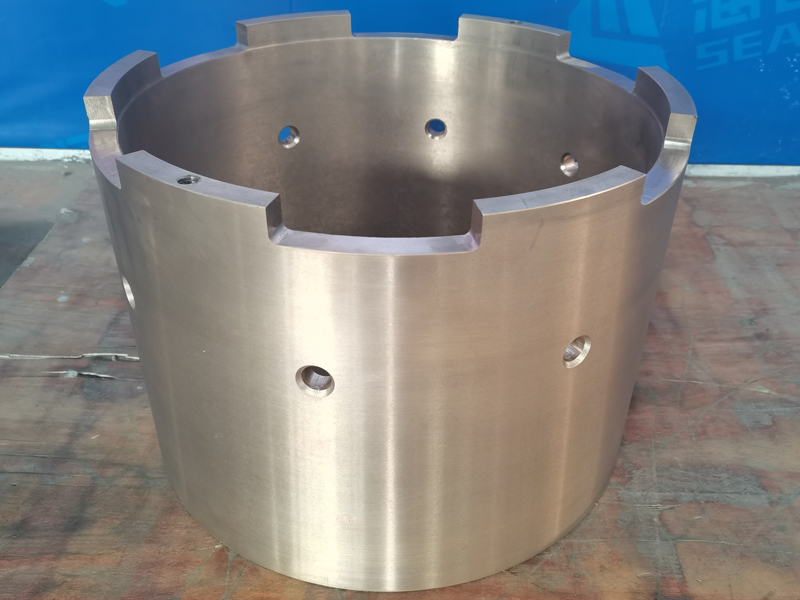

Manufacturing process and supplier selection

Suppliers with good reputation should be selected, and their bronze bushing manufacturing process should be ensured to meet industry standards to ensure product quality and reliability.

In summary, by fully considering these factors, equipment efficiency can be effectively optimized and the service life of the bronze bushing can be extended.