All the products produced by our company are made of sand casting or centrifugal process, according to the manual formula, and are made into blanks after laboratory furnace inspection, and then processed by full CNC program. Both the material and the dimensional accuracy are effectively guaranteed. There are many products on the market that look exactly the same in the picture, but in fact they are made of inferior materials with less than 50% copper content and processed by instrument lathes. In this way, the accuracy of the products cannot be guaranteed, which will definitely bring a lot of trouble to your installation and use in the future.

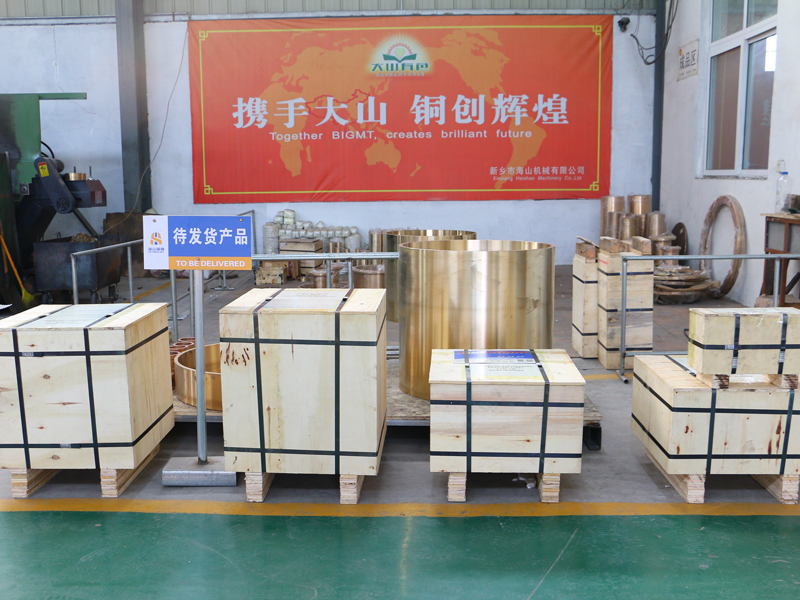

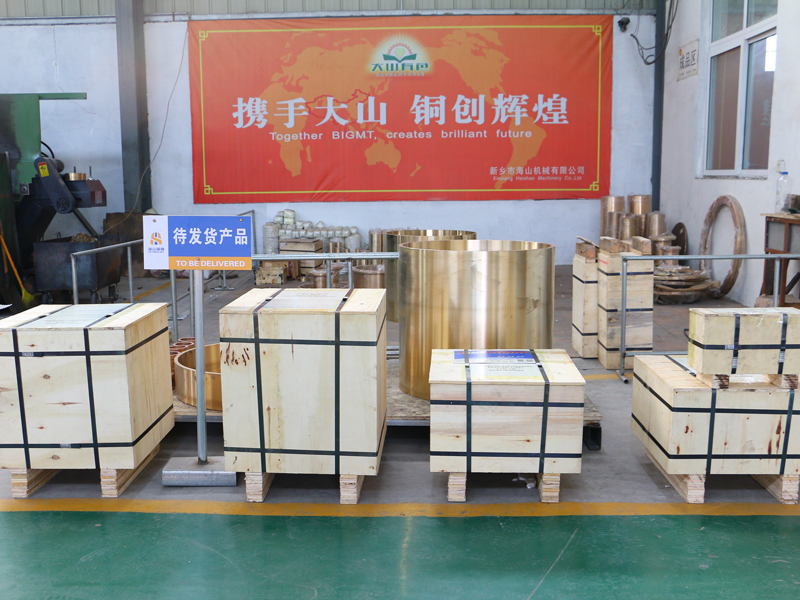

After the product is completed, our logistics staff needs to clean, oil, film pack, and pack in wooden boxes.

Wooden box packaging, the wood board is fumigated and meets the export standards!!!

This is our product packaging. Other manufacturers use strip wood boards or straw ropes instead. Although it saves costs, it will not effectively protect the product during transportation, so please consider it carefully before placing an order.

Real customer comments, with evidence!!!

Physical manufacturers, welcome to visit and inspect.

Related Reading:

Advantages of bronze bushings: the secret to improving mechanical performance

What are the technical requirements for casting wear-resistant tin bronze bushing?

There are several processes for copper casting