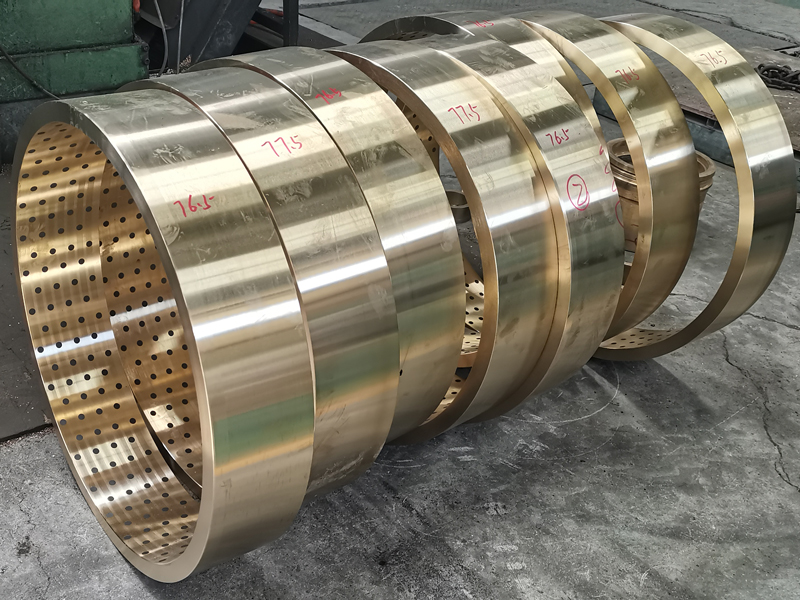

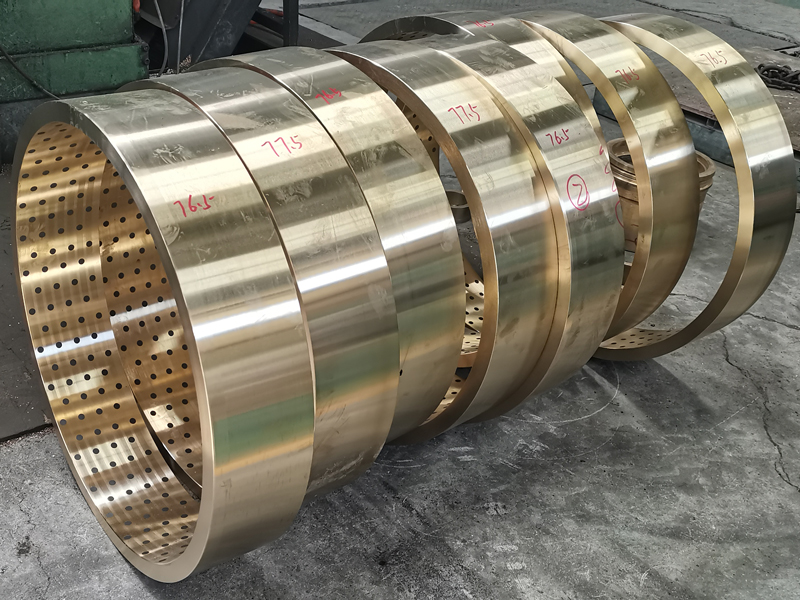

Strong wear resistance:

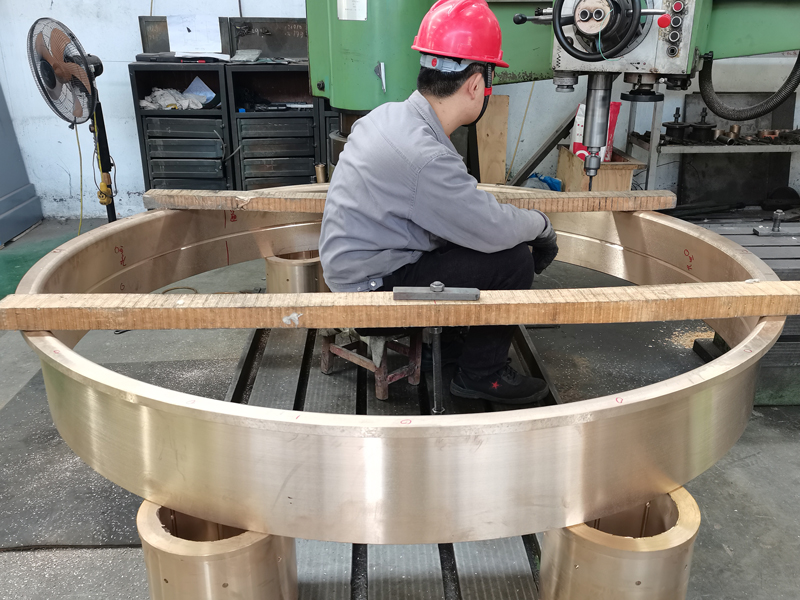

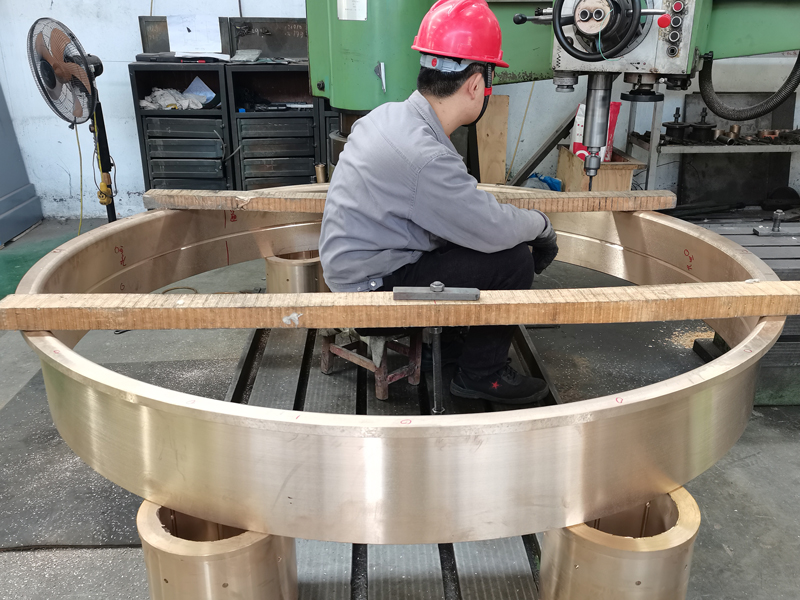

Bronze bushings are made of centrifugal casting and other processes, with a tight internal structure, high hardness, and excellent wear resistance. They are suitable for occasions with high wear resistance requirements such as mining machinery.

Good corrosion resistance: Bronze material has good corrosion resistance, can work stably in atmospheric and freshwater environments, and can resist the erosion of some chemical elements.

Strong pressure resistance: Bronze bushings can withstand large bearing side pressure and can operate normally under high load pressure. Materials such as aluminum bronze and phosphor bronze are often used due to their high hardness.

Regular lubrication and maintenance are required: Bronze bushings require a lot of lubrication during operation to maintain their performance and extend their service life, which makes maintenance relatively difficult.

Widely used: Bronze bushings, as sliding bearings, are widely used in occasions that require high wear resistance, low friction coefficient and good corrosion resistance.

Related Reading:

Casting technology and processing method of wear-resistant bronze bushing

What are the technical requirements for casting wear-resistant tin bronze bushing?

Advantages of bronze alloy castings and their applications in modern industry