Uses and recommendations of commonly used bronze bushing material grades

1.QSn6.5-0.1, QSn6.5-0.4, QSn7-0.2, QSn8-0.3, American Standard C51900, C52100

It has high strength, elasticity, wear resistance and anti-magnetism, good pressure processing in hot and cold states, high flame resistance to electric sparks, can be welded and brazed, good machinability, and corrosion resistance in the atmosphere and fresh water. It is widely used to manufacture elastic components, wear-resistant parts and anti-magnetic parts in precision instruments, such as gears, brush boxes, vibrating plates, contactors, washers, and small shafts

2.QSn6-6-3. QSn5-5-5, American Standard C83600, C93200, C54400

It has medium strength, good wear resistance and corrosion resistance, and excellent cutting performance. Mainly used for wear-resistant and corrosion-resistant parts working under high load and medium sliding speed, such as bearings, bushings, cylinder sleeves, piston clutches, pump glands and worm gears, etc.

3.ZCuSn10Pb1, CuSn12 American Standard C52400

It has high hardness, excellent wear resistance, is not easy to produce seizure, has good casting performance and cutting performance, and has good corrosion resistance in the atmosphere and fresh water. Commonly used for wear-resistant parts working under high load and high sliding speed, such as connecting rods, bushings, bearings, gears, sleeves, worm gears, etc.

4.QAl9-4, QAl10-3-1.5, QAl10-4-4, CuAl10Fe3, ZCuAl9Fe4Ni4Mn2, American Standard C95400, C61900, C95800

It has high strength and good cutting and grinding performance, can be welded, and is easy to heat process and form. Mainly used for manufacturing high-strength bushings, spherical seats, booster sliders, guide screws, driven shafts, support rings, connecting rods, nuts and gears, etc. 5. Lead bronze ZCuPb10Sn10, ZCuPb15Sn8, American Standard C93700, C93800

Good lubrication, wear resistance and corrosion resistance. Manufacture sliding bearings with high surface pressure and side pressure, such as rollers, vehicle bearings, impacted parts with a load peak of 60Mpa, and bimetallic bearings of internal combustion engines with a maximum peak of 100Mpa, as well as piston pin sleeves and friction plates

6. High-strength brass ZCuZn25Al6Mn3Fe3, American Standard C86300

High-strength brass has the highest strength among special brasses. It has high strength, high hardness, high wear resistance, moderate plasticity and good corrosion resistance. Therefore, it is used to cast high-load wear-resistant copper sleeves on heavy machinery, and is often used as oil-free self-lubricating bearings.

Related Reading:

Bronze Bushings Compared to Other Materials: Why Choose Bronze?

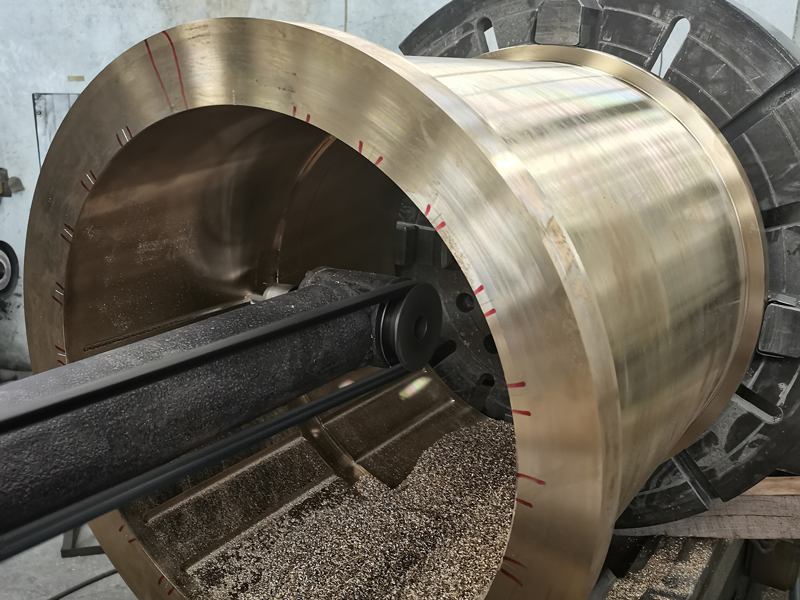

Casting technology and processing method of wear-resistant bronze bushing

How to deal with welding and rust prevention of C86300 tin bronze bushing castings