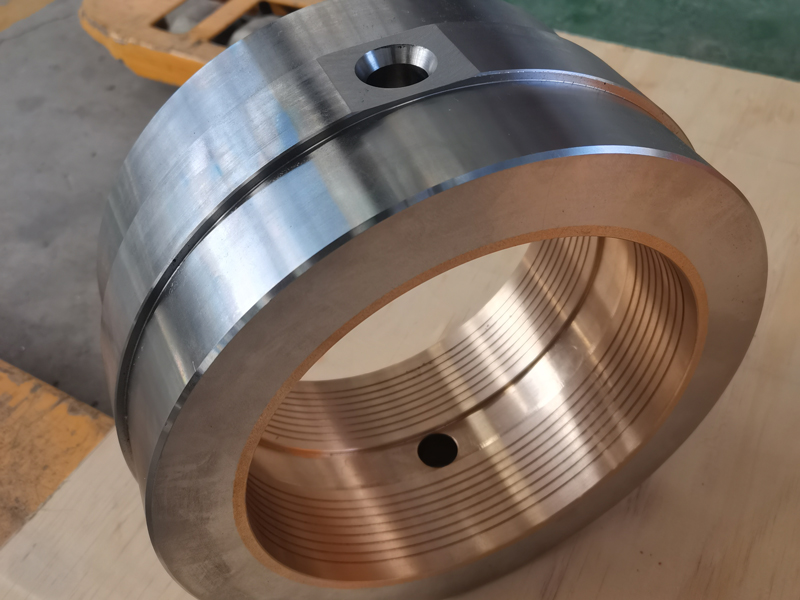

Bronze alloy bushings (copper bushings for short) have been widely used in many mechanical equipment and engineering structures due to their excellent wear resistance, excellent corrosion resistance, excellent thermal conductivity and built-in lubrication properties. The following is an overview of several key application areas of bronze bushings:

1.Heavy machinery field: Bronze bushings play an important role in various types of engineering machinery, construction equipment and mining machinery. They are often used as bearings and sliding components to reduce wear and increase the service life of equipment.

2.Power equipment industry: Thanks to its excellent conductivity and high temperature tolerance, bronze bushings are widely used in motors, generators and transformers, helping to maintain the stable operation of electrical components.

3.Automobile Industry: In automobile engines and gearboxes, bronze bushings serve as bearings and sealing elements, effectively reducing friction, reducing noise, and significantly enhancing the durability of components.

4.Aerospace field: Bronze bushings play an important role in key parts such as aircraft landing gear and engines. They can withstand high loads and friction under extreme conditions, ensuring stable flight performance.

5.Oil and Natural Gas Industry: Because bronze bushings have excellent corrosion resistance and wear resistance, they are very suitable for use in subsea equipment and drilling facilities, especially in marine and humid environments.

6.Water Conservancy Engineering: In water pumps and hydroelectric power generation devices, bronze bushings perfectly adapt to the needs of underwater working environments by improving sealing and wear resistance.

7.Precision Instrument Manufacturing: Bronze bushings are also widely used in high-precision instruments to reduce friction and ensure the stability and long-term service life of the instrument.

8.Railway and Shipping: Bronze bushings are also widely used in key components such as drive shafts and wheel axles of railway vehicles and ships, aiming to improve the wear resistance and corrosion resistance of the components.

The specific material selection of the bronze bushing can be flexibly adjusted according to the actual application environment, such as brass, bronze or other copper alloys, to meet the specific requirements of different application scenarios.

Related Reading:

How to choose the right bronze bushing to optimize equipment efficiency

Advantages of bronze bushings: the secret to improving mechanical performance

Comparison of the differences between aluminum bronze and tin bronze