Copper sleeves (also called copper shaft sleeves or copper bushings) are a common component used in mechanical equipment. They are usually used as sliding bearings, shaft sleeves, bushings, etc., and have high wear resistance and corrosion resistance. The material and performance of copper sleeves depend on the type of copper alloy selected. The following is a detailed introduction to common copper sleeve materials and their performance:

Common copper sleeve materials

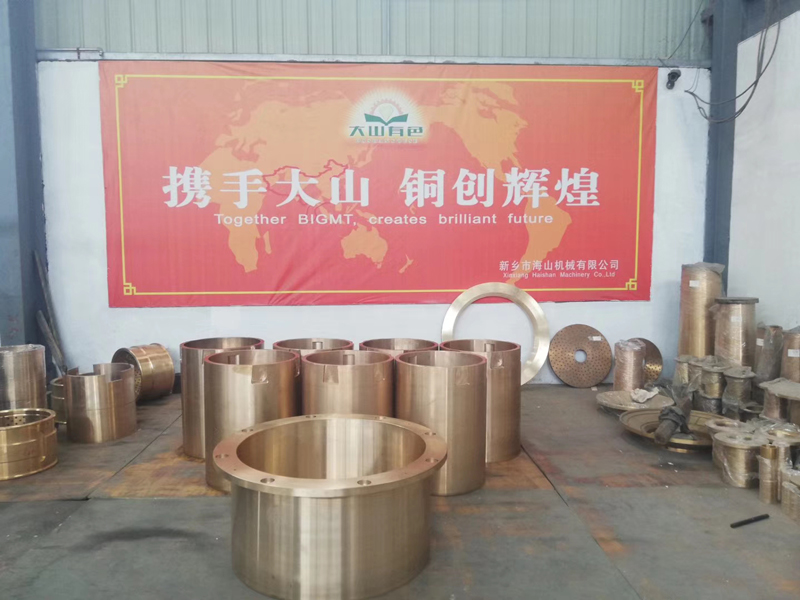

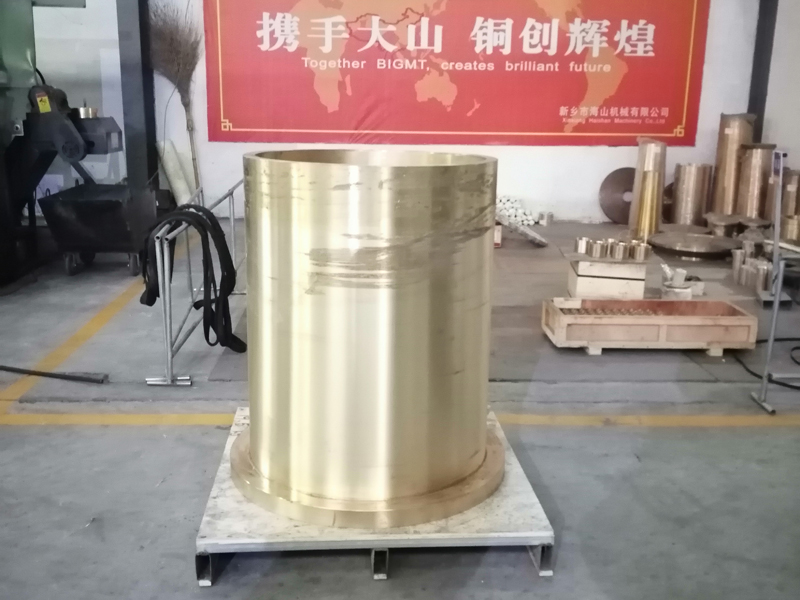

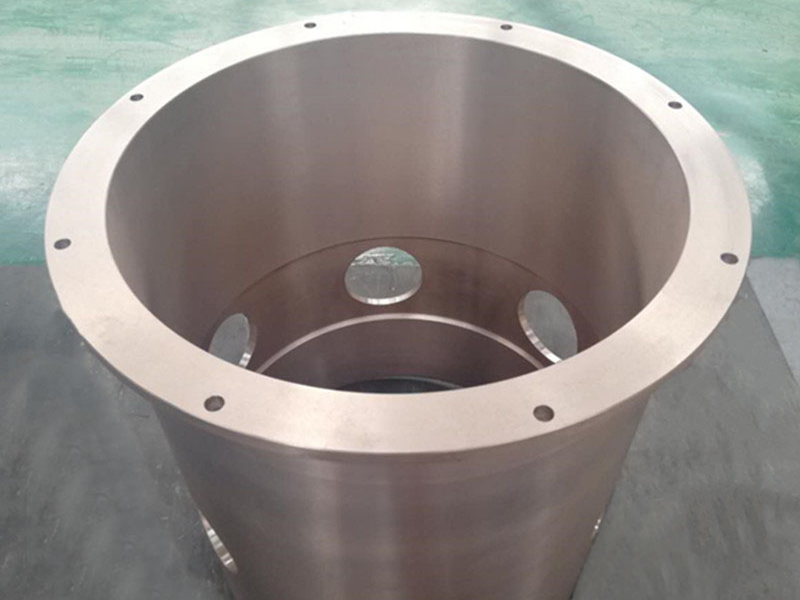

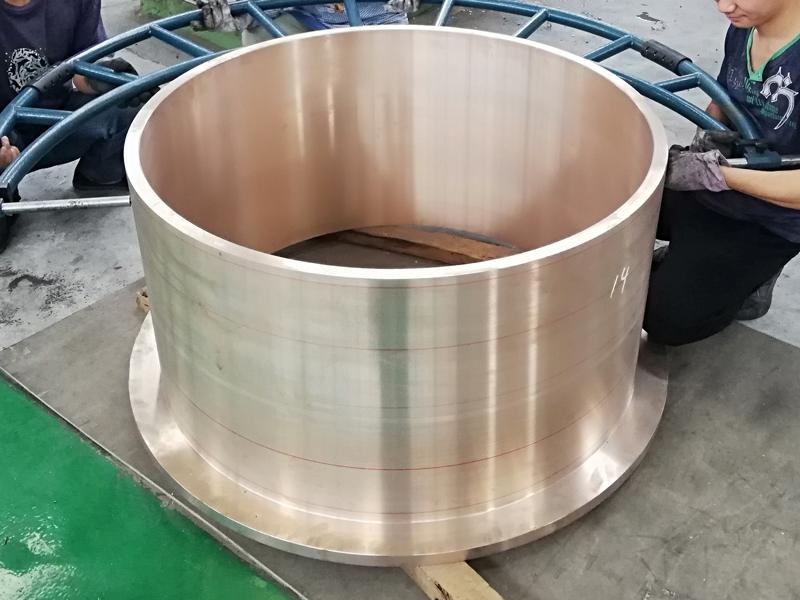

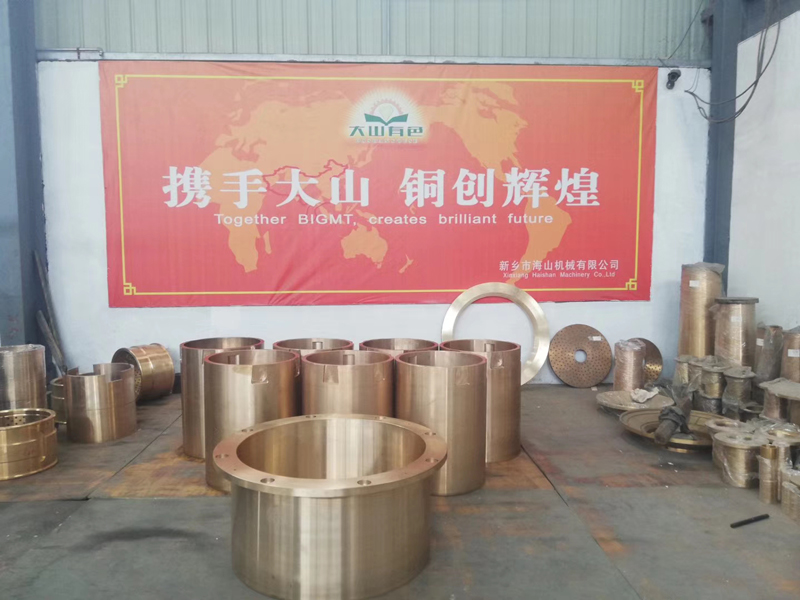

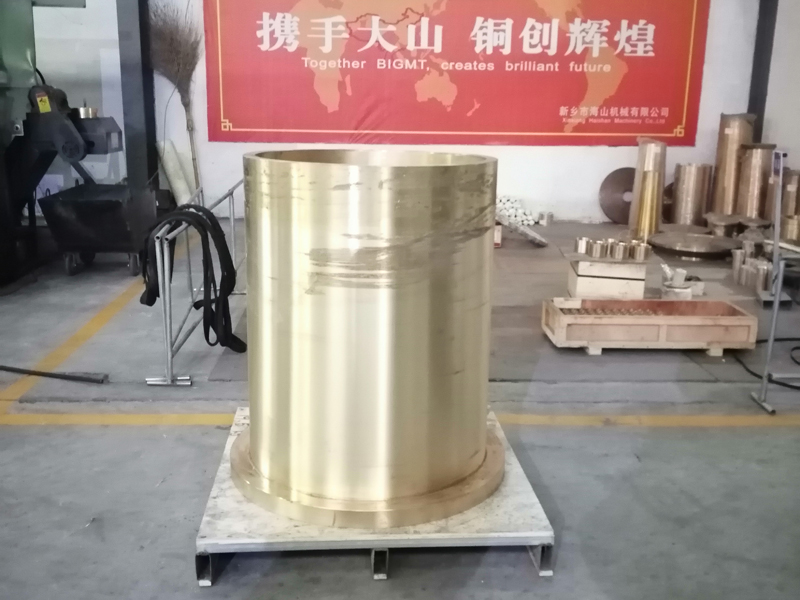

Cast copper sleeves (copper castings)

Cast copper sleeves are copper sleeves produced by casting processes using copper alloy materials. Common types of copper alloys include:

Brass: Mainly composed of copper and zinc, with good strength, corrosion resistance and processability. Brass copper sleeves are usually used in occasions with high requirements for wear resistance and corrosion resistance.

Bronze: Mainly composed of copper and tin or other metals (such as aluminum, manganese, etc.). Bronze sleeves have stronger wear resistance and corrosion resistance and are often used in applications under heavy loads, low speeds or high temperature environments.

Aluminum Bronze: With copper and aluminum as the main components, it has very good corrosion resistance, wear resistance and high temperature performance, and is widely used in marine equipment and chemical equipment.

Phosphor Bronze: Usually composed of copper, tin and phosphorus, it has high elasticity and strength and is suitable for applications with large loads or frequent movements.

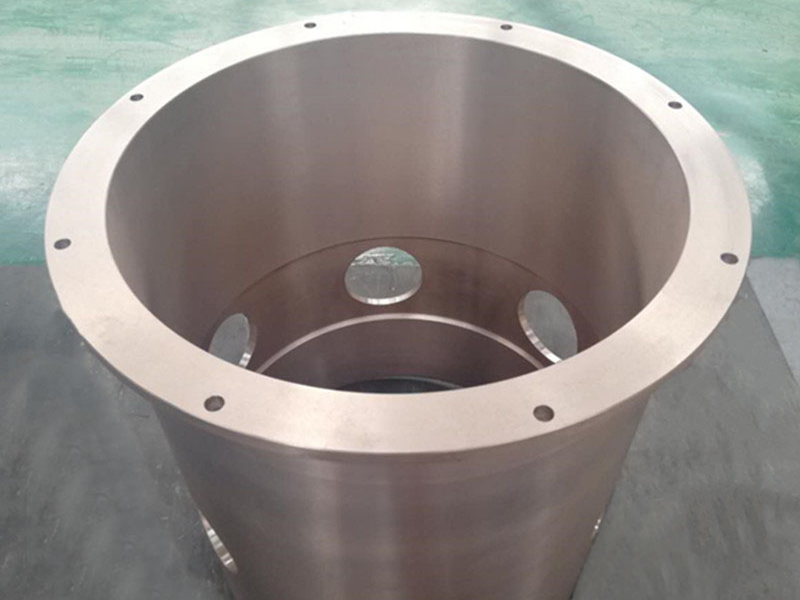

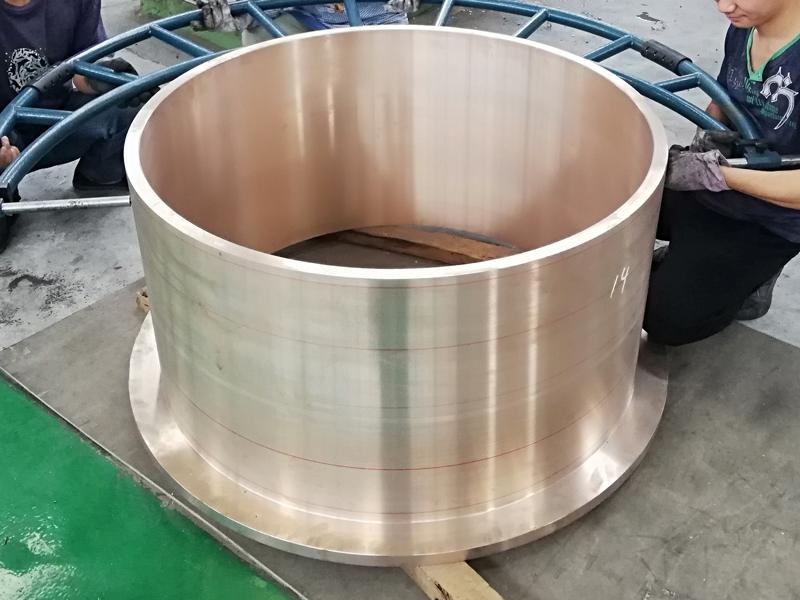

Steel-Copper Composite Sleeve

Steel-Copper Composite Sleeve is composed of a steel substrate and a copper alloy layer, usually made by melting, rolling and other processes. It has higher strength and wear resistance while maintaining the excellent corrosion resistance of copper alloy.

Performance of Copper Sleeve

Wear Resistance

Copper sleeves have excellent wear resistance, especially alloys such as bronze and aluminum bronze. Their wear resistance is suitable for use under high speed and high load conditions. Copper sleeves can effectively reduce wear during friction and extend equipment life.

Corrosion Resistance

Copper and copper alloys have excellent corrosion resistance, especially in wet, acidic and alkaline environments. Aluminum bronze and phosphor bronze have strong resistance to seawater corrosion and are widely used in ships and marine engineering.

Thermal conductivity

Copper has excellent thermal conductivity, which enables copper sleeves to effectively dissipate heat in high temperature environments and prevent overheating. Especially when used for high-temperature, high-speed moving parts, it can ensure the long-term stable operation of the equipment.

High temperature resistance

Some copper alloys (such as aluminum bronze) can still maintain good mechanical properties and stability at high temperatures, so they are often used in high-temperature equipment.

Compressive strength and elasticity

Copper sleeves have high compressive strength and can withstand large loads. Phosphor bronze and aluminum bronze alloys have good elasticity and are suitable for application scenarios requiring good elasticity.

Lubricity

Copper alloys usually have good self-lubrication, which can reduce friction and avoid equipment wear. In addition, the surface of the copper sleeve can further enhance its lubrication properties by adding lubricating oil or grease.

Application of copper sleeves

Mechanical equipment: used for mechanical bearings, sliding bearings, bushings in gear boxes, guide rails, etc., widely used in engineering machinery, mining machinery, metallurgical equipment, etc.

Automotive industry: Bushings for engines, axles, transmissions and other parts.

Ship and marine engineering: Due to the excellent corrosion resistance of copper, bronze and aluminum bronze bushings are often used in bearings and water pumps of ships and other parts.

Power equipment: Friction parts used in motors, generators, transformers and other equipment.

Advantages and disadvantages of copper bushings

Advantages:

Good wear resistance: Extend the service life of the equipment.

Excellent corrosion resistance: Suitable for various harsh environments.

Good thermal conductivity: Able to dissipate heat efficiently.

Self-lubricating: Reduce maintenance frequency and cost.

Disadvantages:

Higher cost: The price of copper alloys is relatively high, which may affect cost control.

Relatively soft: Compared with some steel materials, copper alloys have lower strength and are therefore not suitable for extremely high load applications.

Choosing the right copper bushing material according to the specific use environment and load requirements can significantly improve the performance and reliability of the equipment.