The density of bronze varies depending on its composition and use. Here are the density ranges for several common types of bronze:

1. Tin bronze

Composition: copper + tin (5%-15%)

Density: 8.7 g/cm³ ~ 8.9 g/cm³

Features: Good wear resistance, mainly used for bearings, springs and ship accessories.

2. Aluminum bronze

Composition: copper + aluminum (5%-12%), usually also contains a small amount of iron or nickel

Density: 7.5 g/cm³ ~ 8.4 g/cm³

Features: Strong corrosion resistance, high hardness, used for high-strength mechanical parts, pumps and marine environments.

3. Silicon bronze

Composition: copper + silicon (2%-5%), may contain manganese or nickel

Density: 8.3 g/cm³ ~ 8.8 g/cm³

Features: Strong corrosion resistance, good welding performance, often used in electrical connectors, springs, ship equipment.

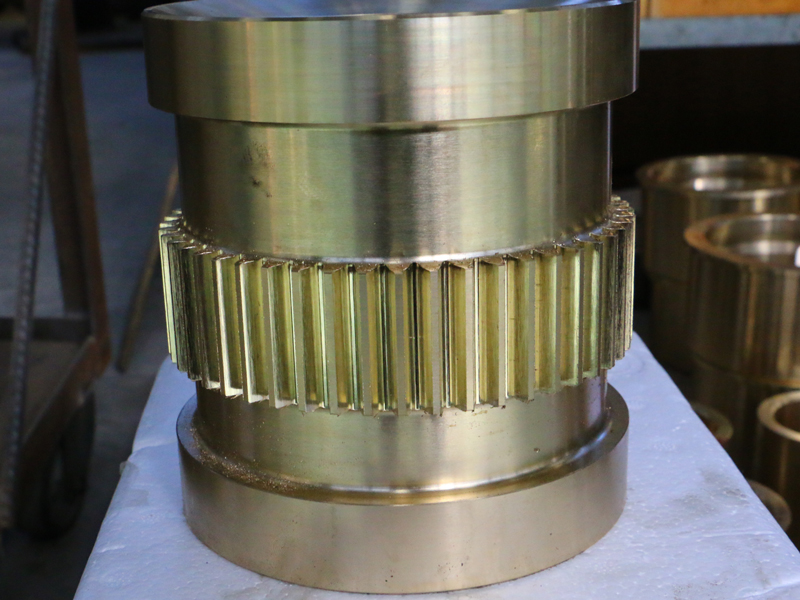

4. Manganese bronze

Composition: copper + manganese (1%-4%), may contain iron and nickel

Density: 7.5 g/cm³ ~ 8.0 g/cm³

Features: high strength, good impact resistance, used in heavy machinery, gears and bushings.

5. Lead bronze

Composition: copper + lead (5%-30%), may contain tin or zinc

Density: 8.9 g/cm³ ~ 9.4 g/cm³

Features: good self-lubricating property, often used in bearings and bushings.

6. Phosphor bronze

Composition: copper + tin (3%-10%) + phosphorus (0.1%-0.3%)

Density: 8.8 g/cm³ ~ 8.9 g/cm³

Features: high elasticity, wear resistance, often used in springs, joints and gears.

For more precise values, please analyze according to the specific bronze formula or refer to the material data sheet.