Everyone knows that

bronze bushing have high hardness and good wear resistance. They are not easy to bite, and they also have good casting performance and machinability. It has strong corrosion resistance. Then it is also very careful in the manufacturing process. So what should we pay attention to in its manufacturing process?

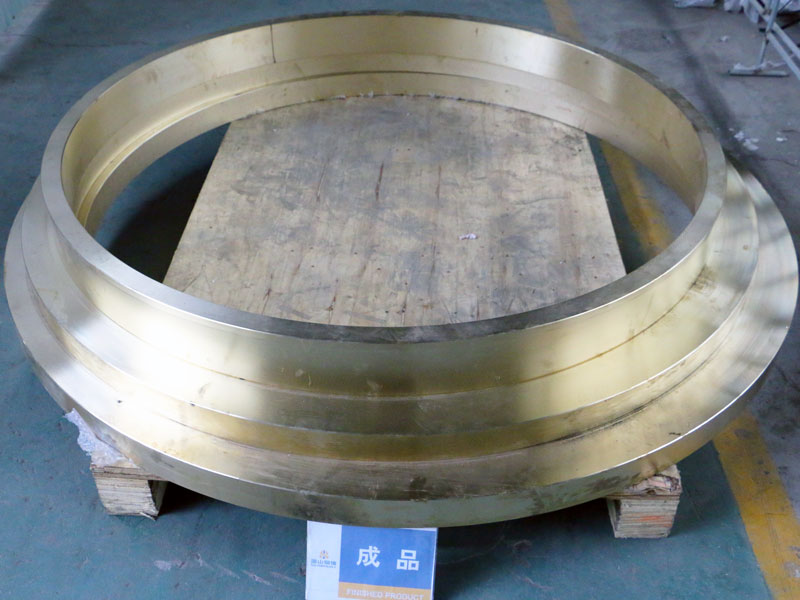

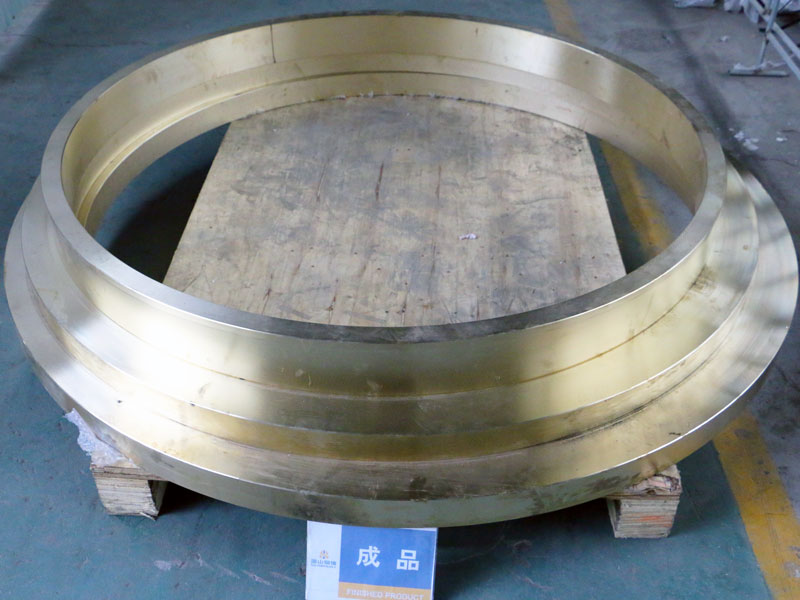

Large bronze bushing

First point: When casting bronze bushing, each process must be carefully handled. For example, the core must be placed straight when the box is assembled, so as to avoid the cast product from being unable to be processed according to size due to this reason.

Second point: Before processing, the casting must be cleaned first, then loaded, calibrated first, and then unloaded when the semi-finished product is processed and cooled. Because bronze has shrinkage, in order to accurately process the workpiece, it must be re-loaded when it is placed at room temperature.

Third point: After the finished product, especially the straight sleeve cannot be placed flat, it should be placed vertically to prevent deformation.

Fourth point: Packing, leave a certain amount to avoid deformation caused by accidental collision during transportation.