The manufacturing process and quality control of

bronze bushings are the key to ensure their performance and service life. The following are some key points abo

ut the manufacturing process and quality control of bronze bushings:

Manufacturing process

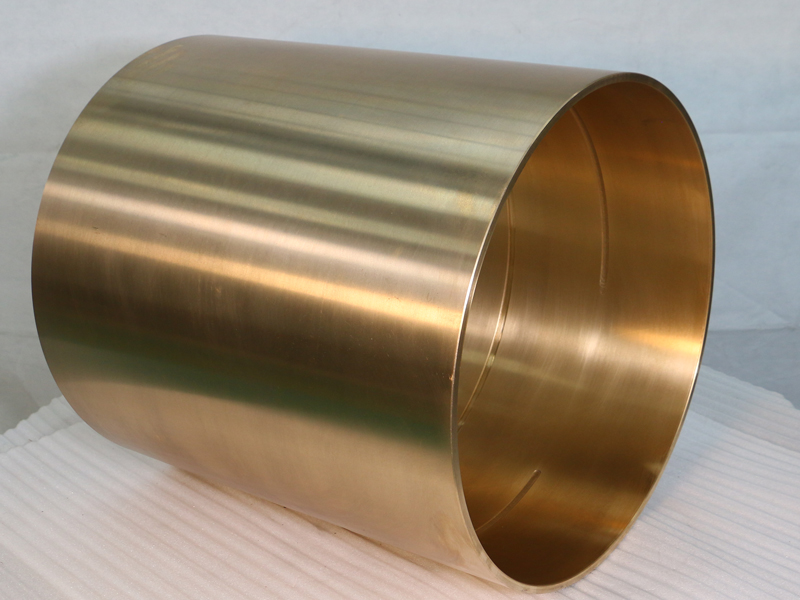

Material selection:

Select suitable bronze alloy materials, commonly used are bronze, brass, etc., which have good mechanical properties and wear resistance.

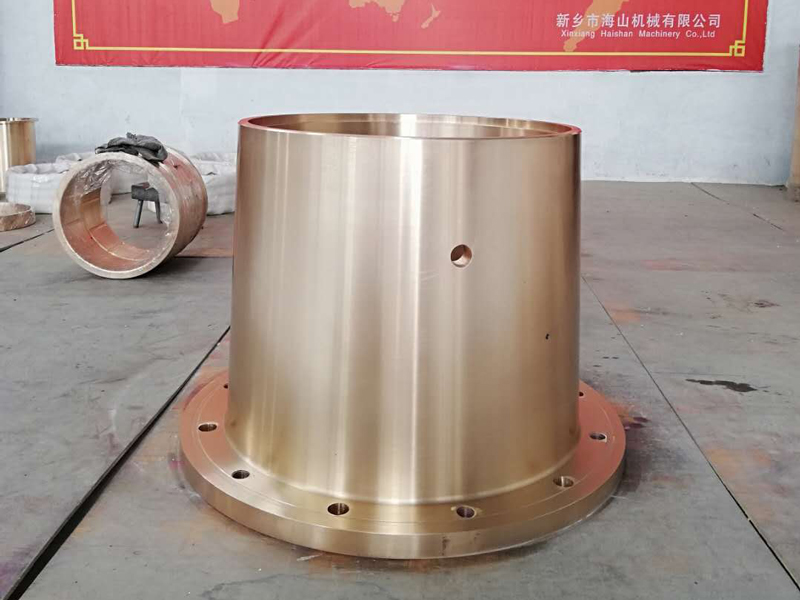

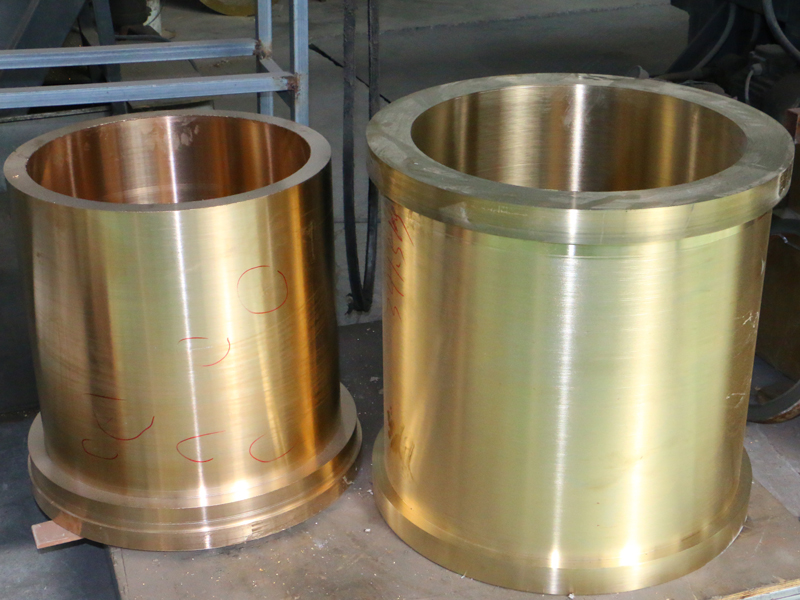

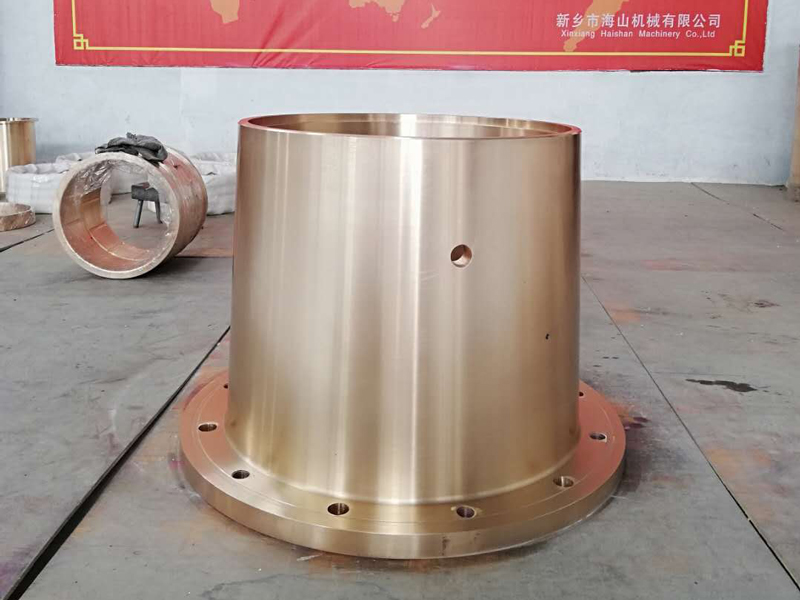

Casting:

The initial shape of the bronze bushings is usually obtained through a casting process, including sand casting and investment casting. The casting process needs to control temperature and fluidity to avoid casting defects.

Forging:

In some applications, the bronze bushings may undergo a forging process to improve the strength and plasticity of the material. The forging process can make the internal structure of bronze tighter and improve wear resistance.

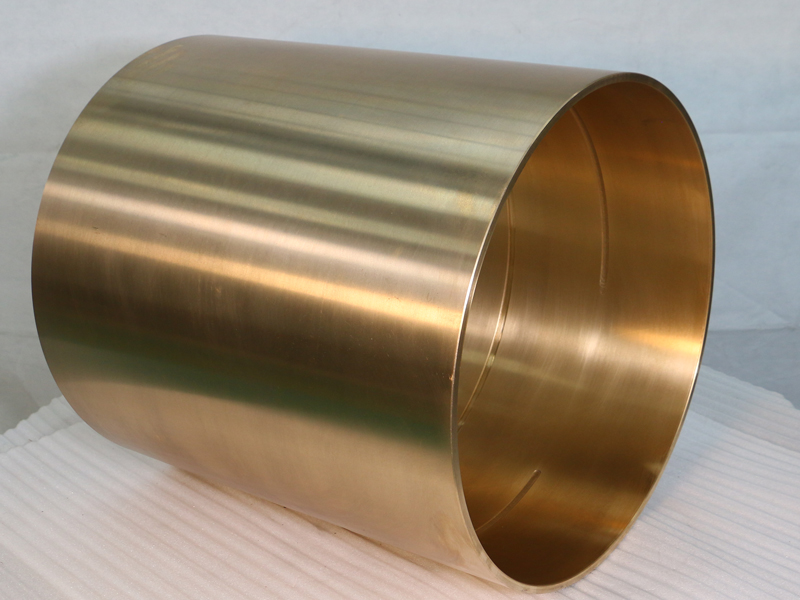

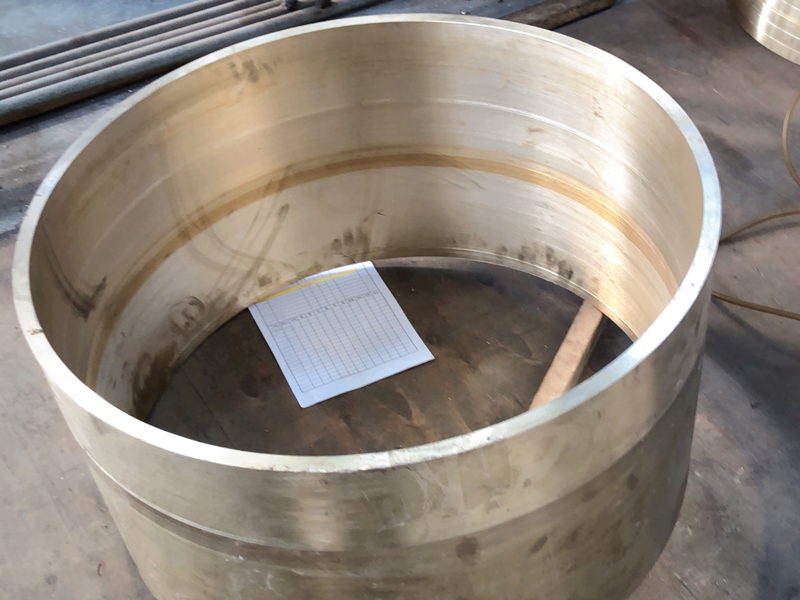

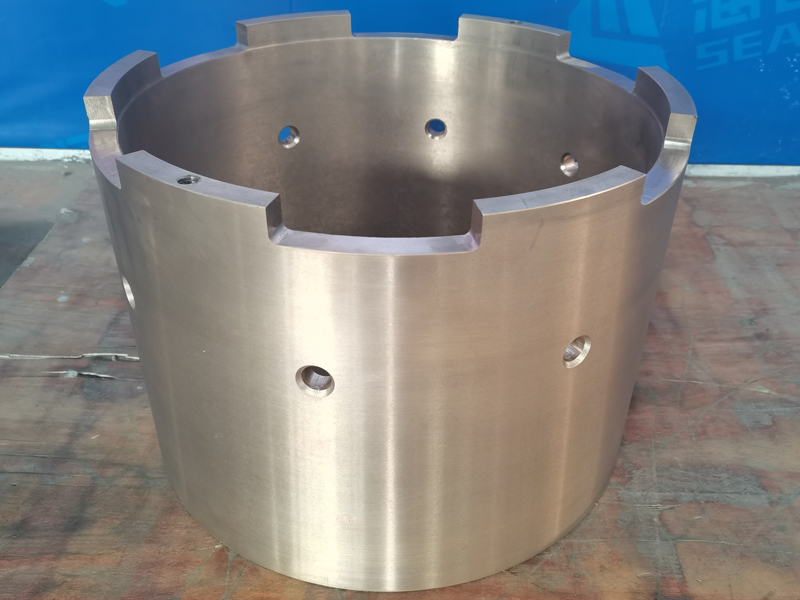

Machining:

Use CNC machine tools or traditional machine tools to fine-process the bronze bushings, including turning, milling, drilling, etc., to achieve the required dimensional tolerance and surface roughness.

Surface treatment:

Depending on the use, the bronze bushings may require surface treatment, such as nickel plating, chrome plating or spraying, to improve its corrosion resistance and wear resistance.

Quality Control

Material Inspection:

Chemical composition analysis and physical property test of raw materials are carried out to ensure that the bronze alloy used meets the design standards.

Process Control:

During the casting and processing process, process parameters such as temperature, pressure, cutting speed, etc. are regularly checked to ensure process stability.

Dimension Inspection:

Use measuring tools and instruments to inspect the dimensions and form and position tolerances of the bronze bushings to ensure that the design requirements are met.

Performance Test:

Mechanical property tests such as tensile test, hardness test and fatigue test are carried out to verify the actual performance of the bronze bushings.

Appearance Inspection:

Check whether there are defects on the surface of the bronze bushings, such as pores, cracks, scratches, etc., to ensure the appearance quality.

Use Data Tracking:

Record the performance of the bronze bushings in actual use, and analyze the data regularly to continuously improve the production process and quality control standards.

Through the above manufacturing process and quality control measures, the high quality and long life of the bronze bushings can be ensured to meet the needs of various industrial applications.

Russian

Russian  Albanian

Albanian  Arabic

Arabic  Amharic

Amharic  Azerbaijani

Azerbaijani  Irish

Irish  Estonian

Estonian  Odia (Oriya)

Odia (Oriya)  Basque

Basque  Belarusian

Belarusian  Bulgarian

Bulgarian  Icelandic

Icelandic  Polish

Polish  Bosnian

Bosnian  Persian

Persian  Afrikaans

Afrikaans  Tatar

Tatar  Danish

Danish  German

German  French

French  Filipino

Filipino  Finnish

Finnish  Frisian

Frisian  Khmer

Khmer  Georgian

Georgian  Gujarati

Gujarati  Kazakh

Kazakh  Haitian Creole

Haitian Creole  Korean

Korean  Hausa

Hausa  Dutch

Dutch  Kyrgyz

Kyrgyz  Galician

Galician  Catalan

Catalan  Czech

Czech  Kannada

Kannada  Corsican

Corsican  Croatian

Croatian  Kurdish (Kurmanji)

Kurdish (Kurmanji)  Latin

Latin  Latvian

Latvian  Lao

Lao  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Kinyarwanda

Kinyarwanda  Romanian

Romanian  Malagasy

Malagasy  Maltese

Maltese  Marathi

Marathi  Malayalam

Malayalam  Malay

Malay  Macedonian

Macedonian  Maori

Maori  Mongolian

Mongolian  Bengali

Bengali  Myanmar (Burmese)

Myanmar (Burmese)  Hmong

Hmong  Xhosa

Xhosa  Zulu

Zulu  Nepali

Nepali  Norwegian

Norwegian  Punjabi

Punjabi  Portuguese

Portuguese  Pashto

Pashto  Chichewa

Chichewa  Japanese

Japanese  Swedish

Swedish  Samoan

Samoan  Serbian

Serbian  Sesotho

Sesotho  Sinhala

Sinhala  Esperanto

Esperanto  Slovak

Slovak  Slovenian

Slovenian  Swahili

Swahili  Scots Gaelic

Scots Gaelic  Cebuano

Cebuano  Somali

Somali  Tajik

Tajik  Telugu

Telugu  Tamil

Tamil  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Welsh

Welsh  Uyghur

Uyghur  Urdu

Urdu  Ukrainian

Ukrainian  Uzbek

Uzbek  Spanish

Spanish  Hebrew

Hebrew  Greek

Greek  Hawaiian

Hawaiian  Sindhi

Sindhi  Hungarian

Hungarian  Shona

Shona  Armenian

Armenian  Igbo

Igbo  Italian

Italian  Yiddish

Yiddish  Hindi

Hindi  Sundanese

Sundanese  Indonesian

Indonesian  Javanese

Javanese  Yoruba

Yoruba  Vietnamese

Vietnamese  Hebrew

Hebrew