The casting and processing customization of

bronze castings mainly involve the following aspects:

1. Casting process

Sand casting

This is one of the most commonly used casting processes, suitable for larger and complex bronze castings, with low cost but high surface roughness.

Precision casting (lost wax casting)

Precision molding through wax molds, suitable for small or complex parts that require high precision and delicate surface treatment.

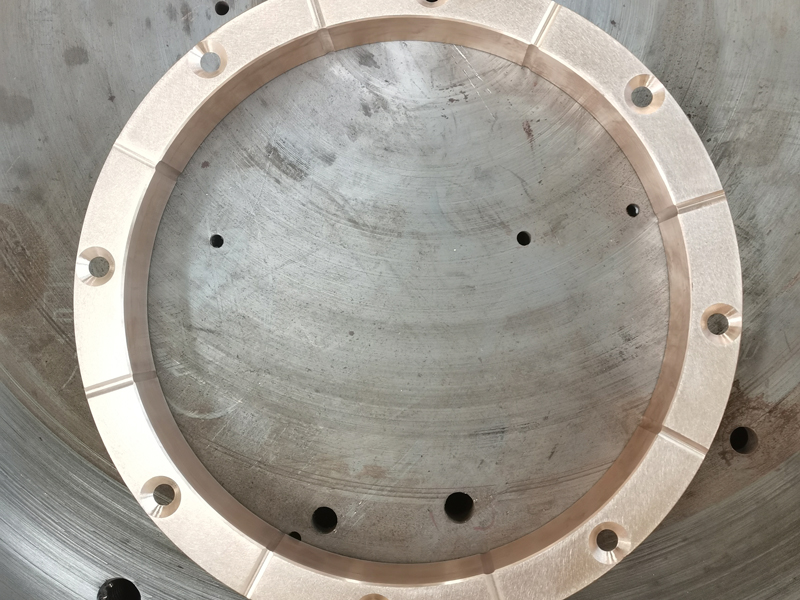

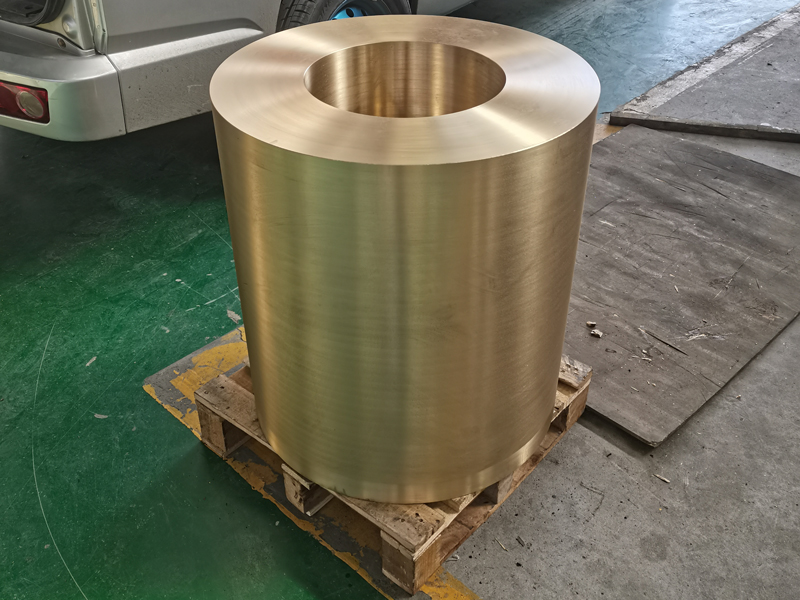

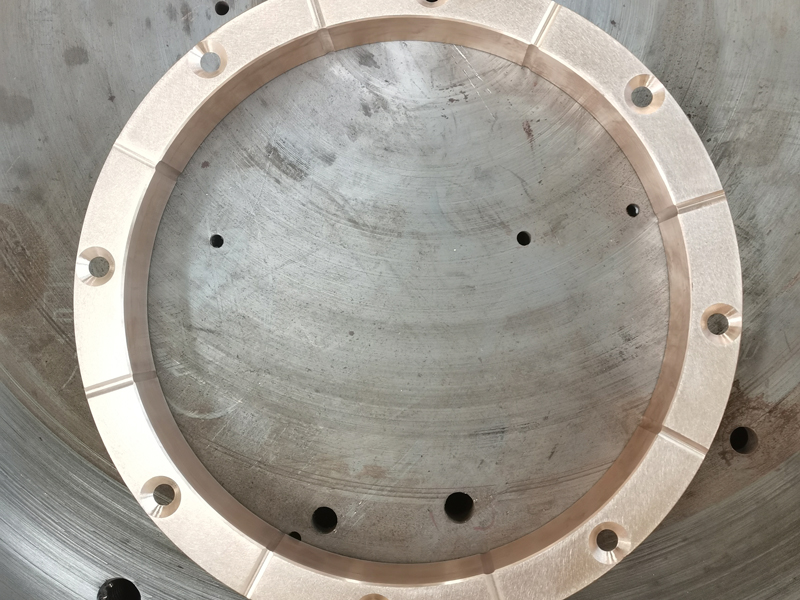

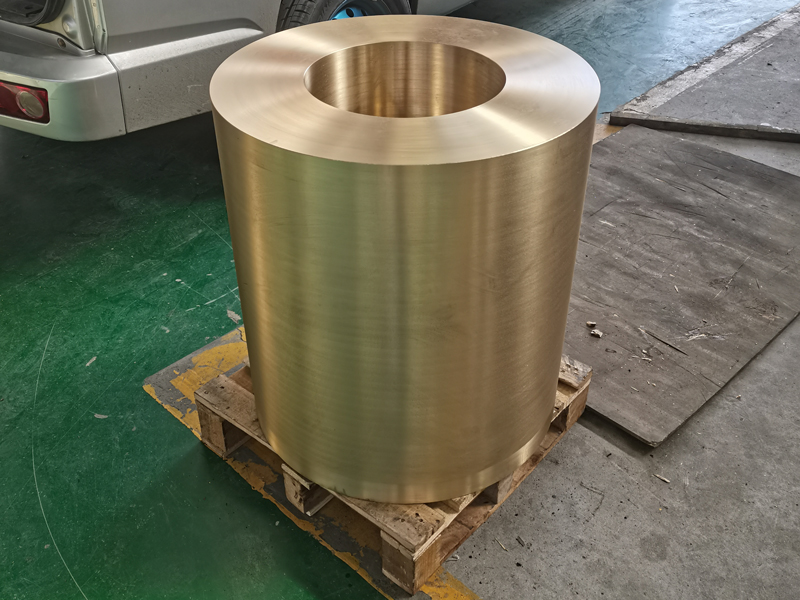

Centrifugal casting

Suitable for the production of hollow, annular bronze parts, such as bronze tubes or bronze rings.

Pressure casting

Small and complex parts used for mass production, with fast production speed and high precision.

Continuous casting

Suitable for the production of large quantities of long bronze materials, such as bronze rods and bronze strips.

2. Processing technology

Machining

Further processing such as turning, milling, drilling, etc. is carried out after casting to obtain the required size and tolerance.

Surface treatment

Includes grinding, polishing and electroplating to improve surface finish and corrosion resistance.

3. Customization process

Design and drawing confirmation

Based on the design drawings or requirements provided by the customer, the manufacturer will conduct 3D modeling and scheme confirmation.

Mold making

The casting mold is made according to the design drawings, and the mold cost will vary according to the complexity.

Sample making and confirmation

The sample is cast according to the mold and sent to the customer for confirmation.

Mass production

After the sample is confirmed, mass production is carried out.

4. Price factors

The price of bronze castings is affected by many factors, including:

bronze material price

bronze is a more expensive metal, and market price fluctuations will directly affect the cost of castings.

Casting process

The cost of different processes varies greatly, and processes such as precision casting and pressure casting are more expensive than sand casting.

Part complexity

The more complex the shape, the more processing technology and time are required, and the cost increases accordingly.

Batch size

Mass production can usually reduce the cost per piece.

Surface treatment

Special treatments such as polishing or electroplating will increase the cost.

5. Approximate price range

The price range of bronze castings is wide, usually ranging from tens of yuan to thousands of yuan per kilogram, depending on the process, material and customization requirements. For example:

Simple sand castings may cost 50-100 yuan per kilogram.

Complex precision casting parts or bronze parts with special surface treatment may cost 300-1000 yuan per kilogram, or even higher.

If you have specific customization needs, it is recommended to contact the foundry directly, provide design drawings or detailed requirements, and obtain a more accurate quotation.