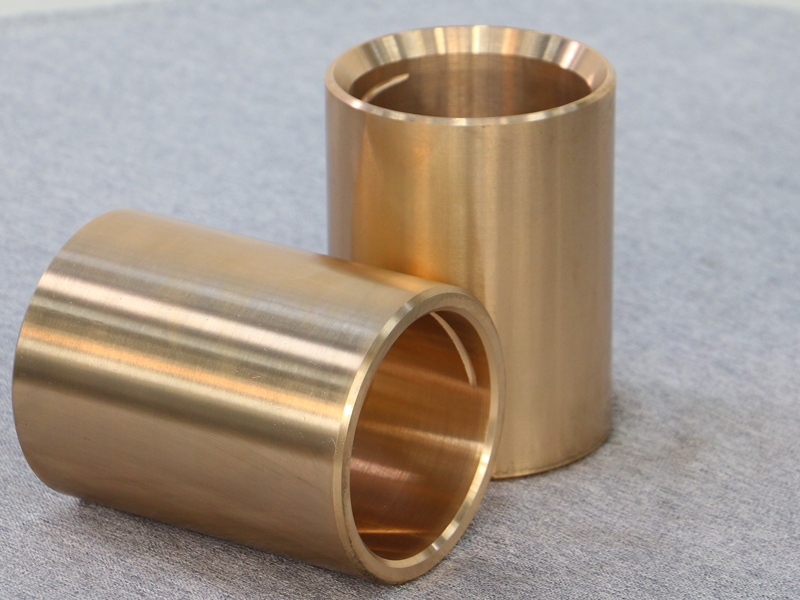

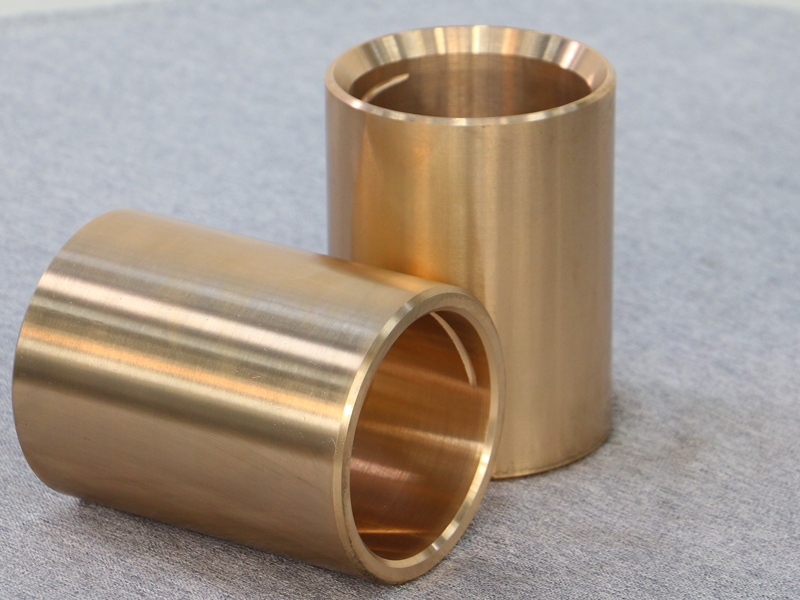

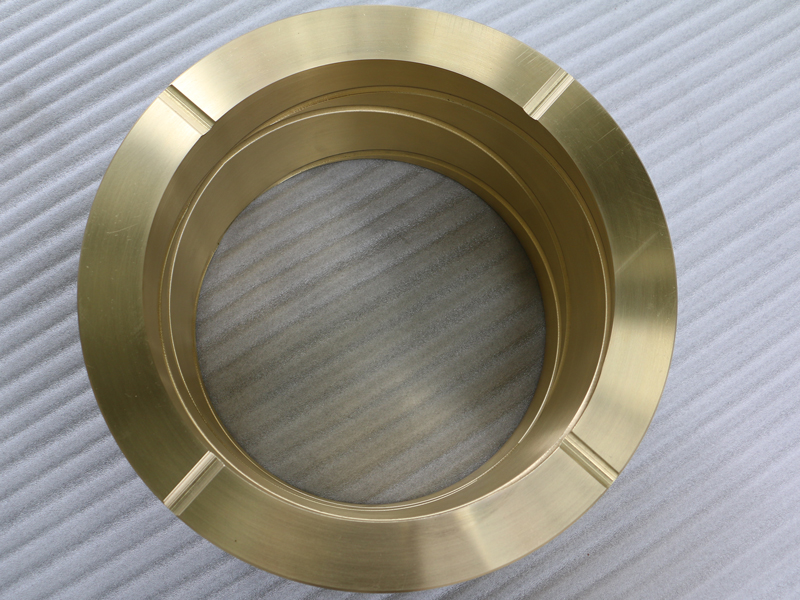

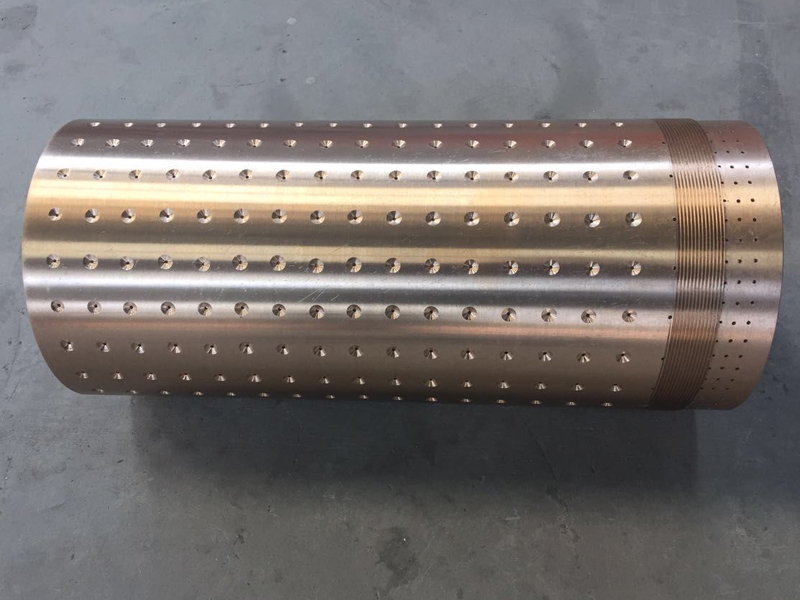

Bronze bushings are widely used as bearing sets in mechanical equipment, especially for applications that require high wear resistance and corrosion resistance. Bronze, as a copper alloy, is usually composed of copper and tin or other metal elements, showing excellent mechanical properties. The following is an in-depth discussion of the wear resistance and corrosion resistance of bronze bushings:

Wear resistance

Material structure: Bronze bushings are usually composed of copper and metals such as tin, aluminum or lead, and the composition ratio can be adjusted according to specific application requirements. For example, both aluminum bronze and tin bronze show high wear resistance, among which tin bronze shows particularly good wear resistance under friction conditions.

Self-lubricating property: Some bronze alloys, such as lead bronze, have the property of retaining lubricants, giving them self-lubricating ability, which can reduce friction under high loads, thereby reducing wear.

Hardness and strength: Bronze is harder than other copper alloy materials, especially in high pressure or friction environments, and can withstand greater mechanical stress, which is one of the important reasons for its high wear resistance.

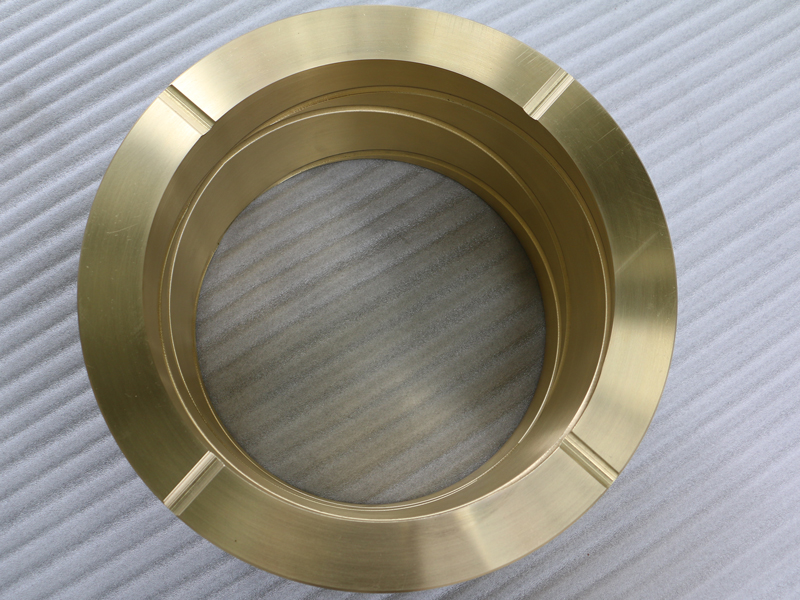

Corrosion resistance

Chemical stability: Bronze has good oxidation resistance and is not easily oxidized or corroded in moisture, acidic environment and other corrosive media (such as seawater), allowing it to be used for a long time in harsh environments.

Acid and alkali resistance: The synergistic effect of copper and other metals in bronze alloys gives it strong corrosion resistance to acid and alkali media, suitable for chemical equipment or marine environments.

Forming a protective layer: When exposed to air or moisture, a dense oxide film will form on the bronze surface, which effectively prevents further corrosion and ensures the stability of the bronze bushings in long-term use.

Typical applications of bronze bushingss:

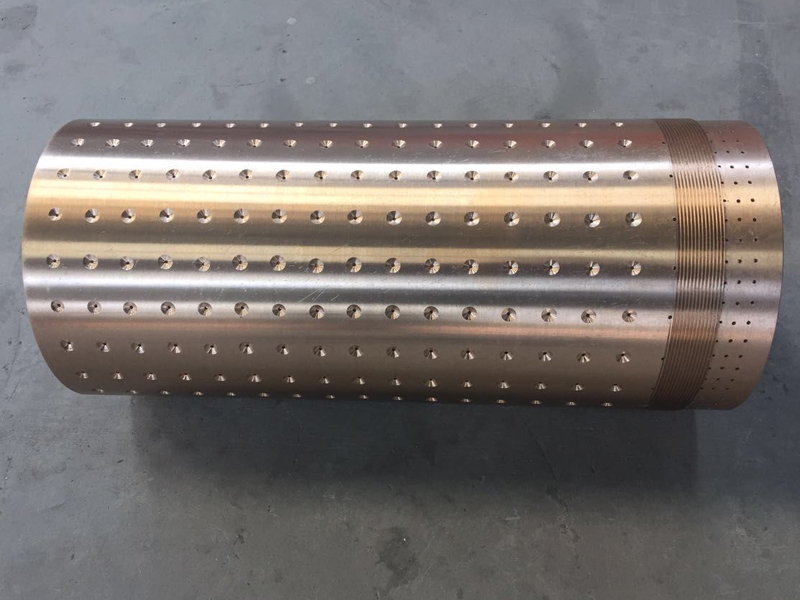

Bearings and gears: Bronze bushingss are often used in bearings and gears that require high wear resistance, especially under limited lubrication conditions.

Ships and marine equipment: Thanks to their corrosion resistance, bronze bushingss are widely used in bearings and accessories of marine equipment and can remain stable for a long time in humid environments.

Mining and mechanical equipment: In high-wear and heavy-load applications, such as crushers and excavators, bronze bushingss are favored for their high wear resistance.

Summary:

The wear resistance and corrosion resistance of bronze bushings make them an indispensable component in the machinery industry, especially suitable for long-term use in high-wear and corrosive environments.