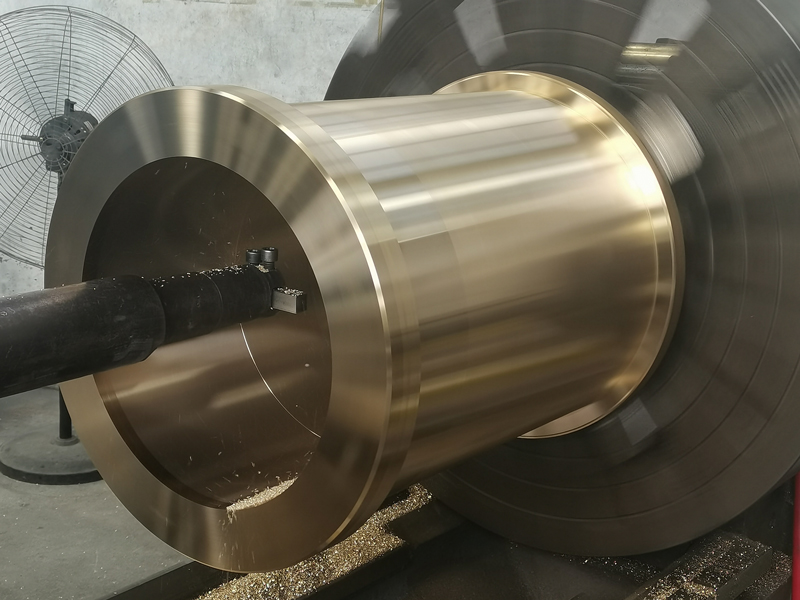

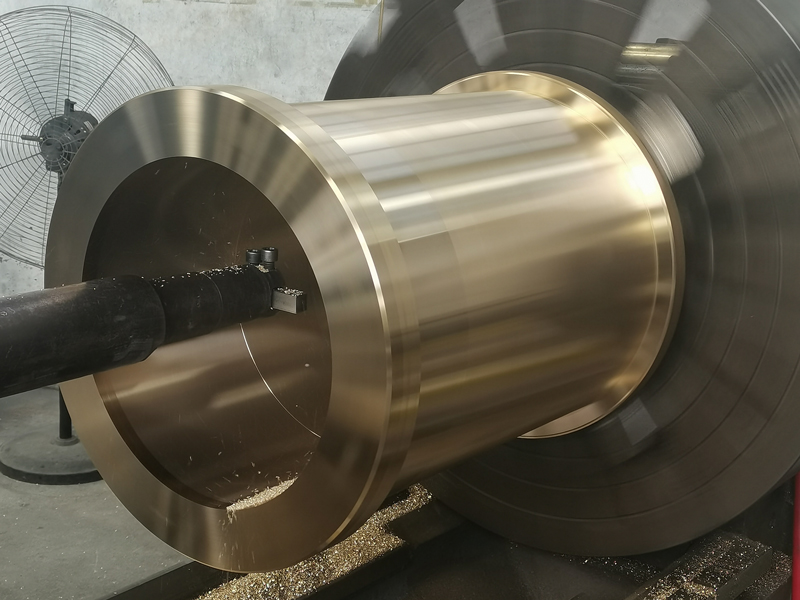

The main consideration for choosing

bronze (copper alloy) as bushings, bushings or other mechanical components is due to its unique multiple advantages compared to other materials:

Excellent wear resistance:

Bronze has excellent wear resistance, especially under high load and low speed operating conditions. Bronze bushings experience significantly less wear in frictional environments than materials such as cast iron or steel, making them more suitable for use in high-friction mechanical components.

Excellent self-lubricating properties:

Bronze alloys have self-lubricating capabilities, especially oil-impregnated bronze, which greatly reduces the need for additional lubricants in mechanical systems, helping to reduce maintenance costs and significantly extend the service life of equipment.

Strong corrosion resistance:

Bronze has extremely high resistance to a variety of corrosive media, especially in marine environments or in contact with water or acidic solutions. Therefore, it is often used as the material of choice for ship parts or machinery in contact with water.

High load carrying capacity:

Bronze has excellent load-bearing capacity and can maintain stable mechanical properties under heavy loads. This makes it very suitable for use in applications that need to withstand greater pressure, such as bushings, gears and other key components.

Excellent thermal conductivity:

Bronze has good thermal conductivity, which helps to effectively dissipate heat and prevent mechanical parts from failing due to overheating. This characteristic is particularly important in mechanical components working in high temperature environments.

Excellent shock absorption performance:

Bronze bushings have outstanding performance in shock absorption and mechanical vibration absorption, which can effectively reduce mechanical fatigue or damage caused by vibration and improve the reliability and service life of equipment.

Easy to process and manufacture:

Bronze is relatively easy to machine and cast, so it is less expensive and produces better results when manufacturing complex-shaped mechanical parts, giving manufacturers more design and production flexibility.

Comparison with other materials:

Steel: Although steel is stronger, it is not as corrosion- and wear-resistant as bronze and requires more frequent lubrication maintenance.

Cast Iron: Cast iron has lower cost, but has poor impact resistance, and its wear resistance and lubrication properties are not as good as bronze.

Plastic: Plastic bushings are cheaper and have better self-lubricating properties, but they have limited load-bearing capacity, are not resistant to high temperatures, and are easily deformed, which limits their application in high-demand situations.

The main reason for choosing bronze bushings is its superior comprehensive performance, which is especially suitable for applications requiring high wear resistance, corrosion resistance and large load-bearing capacity. In machinery and equipment, especially in harsh environments, bronze offers significant advantages.