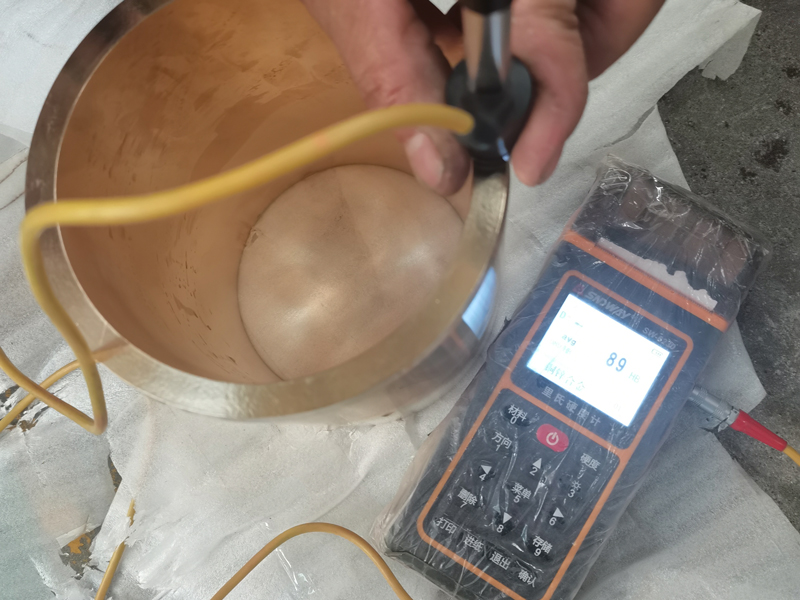

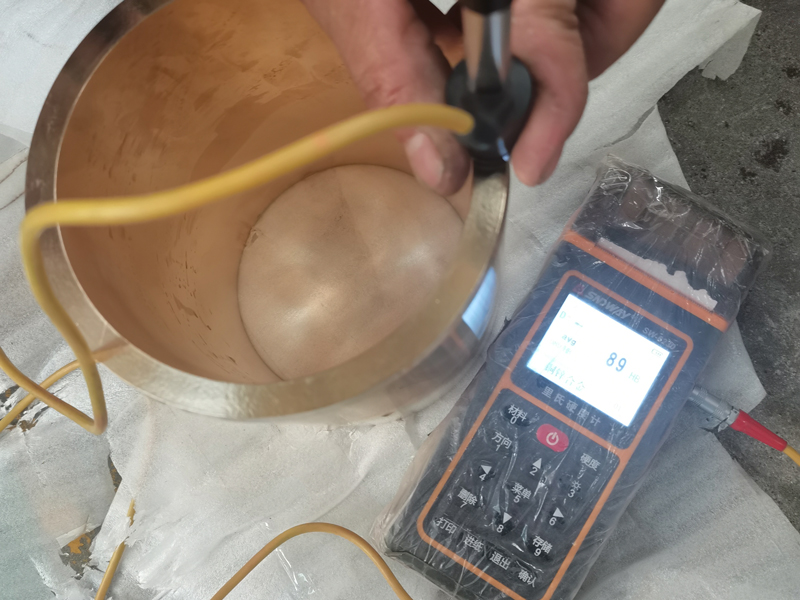

Mechanical property test of

bronze bushing

Hardness test: The hardness of bronze bushing is a key indicator. The hardness of bronze with different alloy compositions varies. For example, the hardness of pure copper is 35 degrees (Boling hardness tester), while the hardness of tin bronze increases with the increase of tin content, ranging from 50 to 80 degrees.

Wear resistance test: Bronze bushings need to have good wear resistance to ensure stable performance in long-term use. Wear resistance test can evaluate its wear resistance by conducting friction and wear tests simulating actual working conditions.

Tensile strength and yield strength test: Tensile strength and yield strength reflect the ability of materials to resist deformation and fracture when subjected to force. For bronze bushings, these indicators must meet the design requirements to ensure that they will not break or deform when subjected to pressure.

The mechanical property test of bronze bushings is an important link to ensure its quality and performance, and must be carried out strictly in accordance with relevant standards and specifications.

Related Reading:

Material standards and working principles of self-lubricating bronze bushings

What should be paid attention to when using composite bronze bushing

Centrifugal casting process and technical requirements of tin bronze bushing