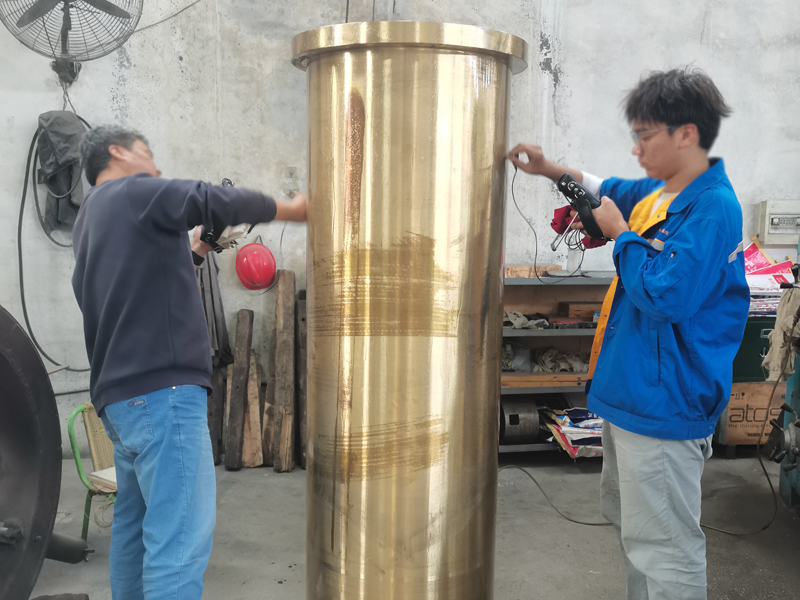

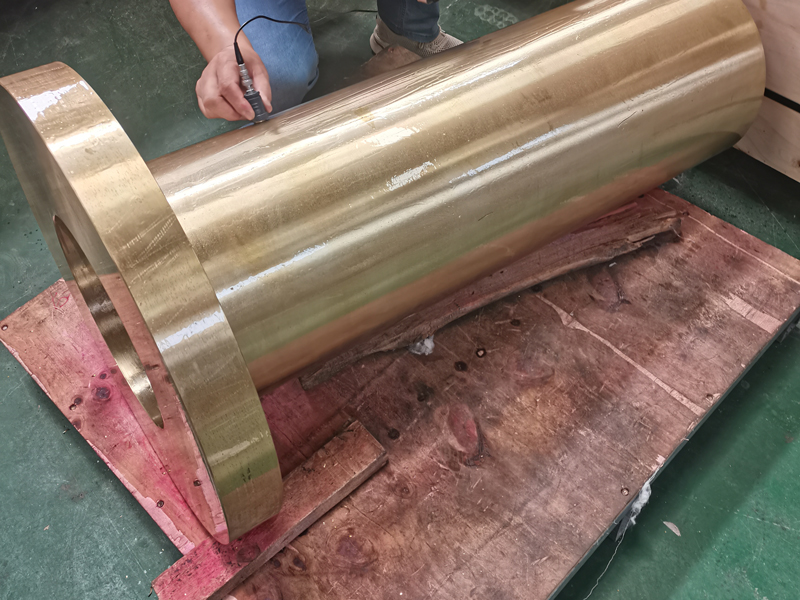

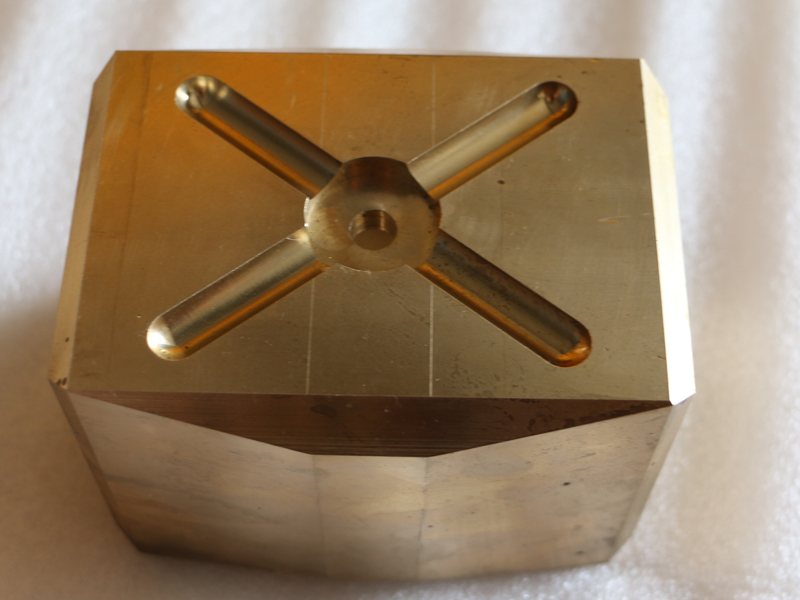

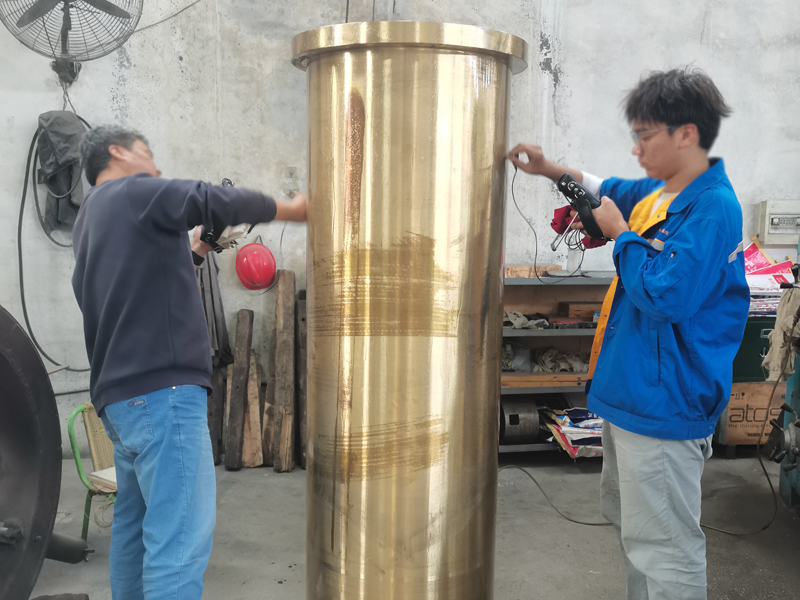

Inspection requirements and precautions for

bronze castings

Inspection requirements:

1.Surface quality inspection: 5B test, salt spray test, and UV resistance test are required to ensure that the surface quality of castings meets the standards.

2.Shape and size inspection: According to the use requirements, flatness, parallelism, straightness and other inspections are carried out to ensure that the shape and size of the castings meet the design requirements.

3.Internal quality inspection: Including chemical composition, mechanical properties, etc., to ensure that the internal quality of the castings meets the standards.

Precautions:

1.Comprehensive inspection method: For discontinuities that cannot be measured by radiographic inspection, other non-destructive inspection methods should be considered.

2.Special applications: For special applications, more stringent inspection methods need to be formulated and determined through negotiation between the buyer and the supplier.

3.Safety and health: Before using the inspection standards, users should conduct corresponding safety and health training and establish rules and regulations.

Inspection requirements and precautions for bronze castings are important links to ensure that the quality of castings meets the standards. Inspections and precautions should be strictly implemented in accordance with relevant standards and requirements.

Related Reading:

Importance of Bronze (Copper) Bushing Packaging

The corrosion problem of copper bushing (bronze casting) should be taken seriously

How to deal with welding and rust prevention of C86300 tin bronze bushing castings

Russian

Russian  Albanian

Albanian  Arabic

Arabic  Amharic

Amharic  Azerbaijani

Azerbaijani  Irish

Irish  Estonian

Estonian  Odia (Oriya)

Odia (Oriya)  Basque

Basque  Belarusian

Belarusian  Bulgarian

Bulgarian  Icelandic

Icelandic  Polish

Polish  Bosnian

Bosnian  Persian

Persian  Afrikaans

Afrikaans  Tatar

Tatar  Danish

Danish  German

German  French

French  Filipino

Filipino  Finnish

Finnish  Frisian

Frisian  Khmer

Khmer  Georgian

Georgian  Gujarati

Gujarati  Kazakh

Kazakh  Haitian Creole

Haitian Creole  Korean

Korean  Hausa

Hausa  Dutch

Dutch  Kyrgyz

Kyrgyz  Galician

Galician  Catalan

Catalan  Czech

Czech  Kannada

Kannada  Corsican

Corsican  Croatian

Croatian  Kurdish (Kurmanji)

Kurdish (Kurmanji)  Latin

Latin  Latvian

Latvian  Lao

Lao  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Kinyarwanda

Kinyarwanda  Romanian

Romanian  Malagasy

Malagasy  Maltese

Maltese  Marathi

Marathi  Malayalam

Malayalam  Malay

Malay  Macedonian

Macedonian  Maori

Maori  Mongolian

Mongolian  Bengali

Bengali  Myanmar (Burmese)

Myanmar (Burmese)  Hmong

Hmong  Xhosa

Xhosa  Zulu

Zulu  Nepali

Nepali  Norwegian

Norwegian  Punjabi

Punjabi  Portuguese

Portuguese  Pashto

Pashto  Chichewa

Chichewa  Japanese

Japanese  Swedish

Swedish  Samoan

Samoan  Serbian

Serbian  Sesotho

Sesotho  Sinhala

Sinhala  Esperanto

Esperanto  Slovak

Slovak  Slovenian

Slovenian  Swahili

Swahili  Scots Gaelic

Scots Gaelic  Cebuano

Cebuano  Somali

Somali  Tajik

Tajik  Telugu

Telugu  Tamil

Tamil  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Welsh

Welsh  Uyghur

Uyghur  Urdu

Urdu  Ukrainian

Ukrainian  Uzbek

Uzbek  Spanish

Spanish  Hebrew

Hebrew  Greek

Greek  Hawaiian

Hawaiian  Sindhi

Sindhi  Hungarian

Hungarian  Shona

Shona  Armenian

Armenian  Igbo

Igbo  Italian

Italian  Yiddish

Yiddish  Hindi

Hindi  Sundanese

Sundanese  Indonesian

Indonesian  Javanese

Javanese  Yoruba

Yoruba  Vietnamese

Vietnamese  Hebrew

Hebrew