Bronze, an alloy of copper and other metals such as tin and aluminum, is a widely used metal material in the early history of mankind. Its unique properties make it shine in many fields.

Basic properties of bronze

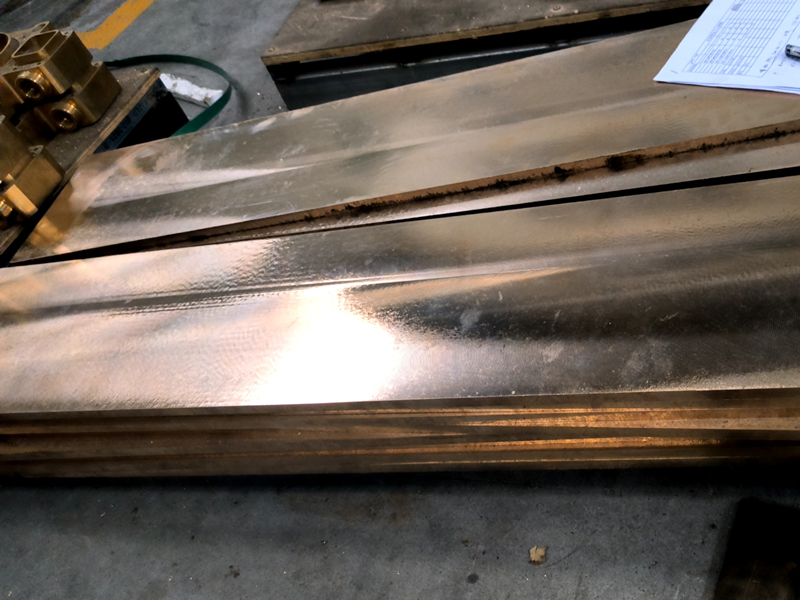

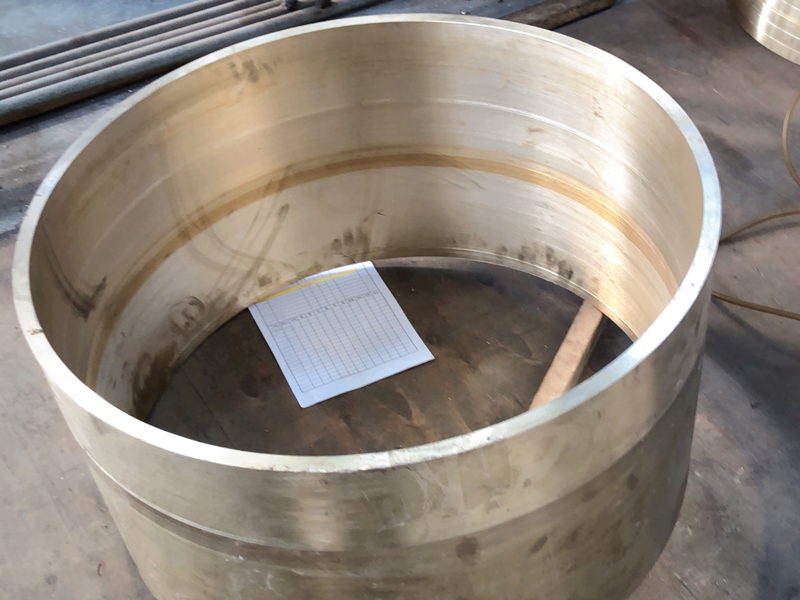

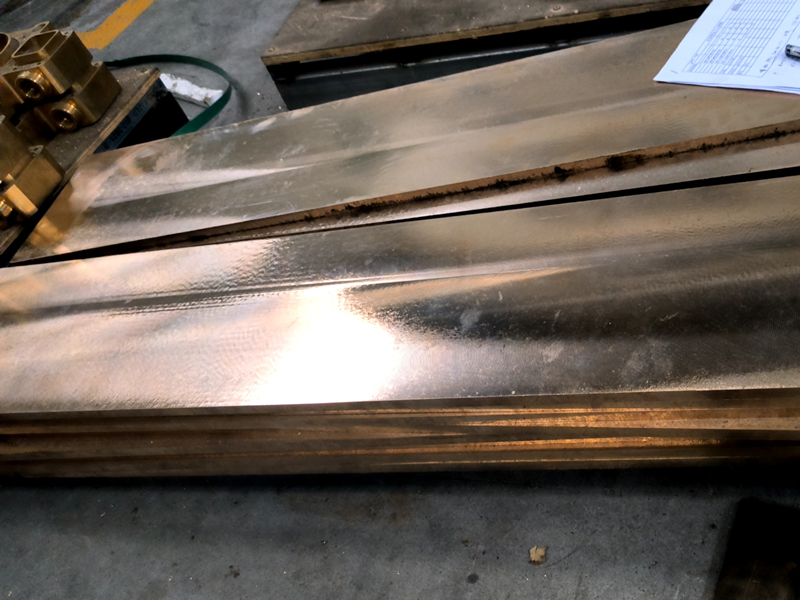

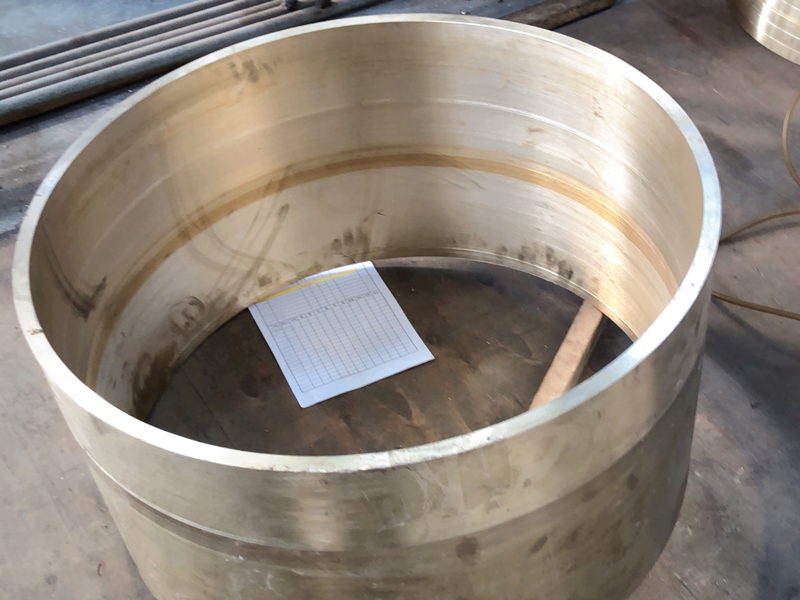

Excellent mechanical properties: high hardness, high strength, and wear resistance make it an ideal material for manufacturing mechanical parts.

Strong corrosion resistance: especially excellent performance in humid and seawater environments, extending service life.

Good casting performance: easy to melt and shape, and can be processed into complex shapes.

Low friction coefficient: smooth surface, reduced friction, suitable for mechanical transmission.

Animagnetic and conductive properties: excellent conductivity and unaffected by magnetic fields.

Main application areas of bronze

Mechanical manufacturing: transmission parts such as bearings, gears, nuts, and tools such as stamping dies and sliders.

Electrical and electronic: electrical components such as switches, contactors, and springs and connectors in electronic equipment.

Architecture and decoration: high-end building materials such as door and window hardware, sculptures and artworks.

Shipbuilding and marine engineering: propellers, valves and other ship parts, as well as marine engineering equipment.

Military and industry: historical military equipment, as well as valves, pump parts, etc. in modern industry.

Musical instrument making: bells, gongs, cymbals and other percussion instruments, showing good resonance performance.

Classification and specific uses of bronze

Tin bronze: containing 5%-15% tin, suitable for bearings, gears, etc.

Aluminum bronze: containing 5%-12% aluminum, used for ship accessories and wear-resistant parts.

Phosphorus bronze: adding phosphorus to improve wear resistance and elasticity, used for springs and bearings.

Beryllium bronze: high hardness, good elasticity, suitable for electronic components and high-precision tools.

Bronze, this ancient and superior alloy material, still plays an important role in many fields, showing its irreplaceable value. With the development of materials science, the performance and application of bronze will continue to expand, contributing to industrial and social progress.

Related Reading:

Mechanical properties test of bronze bushing

Manufacturing process and quality control of bronze bushings

Causes and solutions for segregation of bronze castings