Mine electromechanical equipment is an important part of mine production, and its good operating condition directly affects production efficiency, safety and economic benefits. The following are the key points and practical suggestions for the maintenance of mine electromechanical equipment.

The importance of mine electromechanical equipment maintenance

Ensure the safe operation of equipment

Regular maintenance can discover and eliminate potential hidden dangers, reduce equipment failure rate, and reduce the occurrence of safety accidents.

Extend the service life of equipment

Reasonable maintenance measures can effectively slow down the wear of equipment parts and extend the economic life of equipment.

Improve production efficiency

Maintain the best operating state of equipment and reduce downtime caused by equipment failure.

Reduce maintenance costs

Preventive maintenance is lower than the cost of fault repair, which can avoid high costs caused by major damage to equipment.

Common maintenance methods for mine electromechanical equipment

1. Preventive maintenance

Regular inspection: Check key components regularly according to the equipment manual or operating conditions.

For example: cleaning and tightening of motors, cables, transmission systems, etc.

Lubrication maintenance: Regularly add lubricating oil to transmission parts to avoid friction, overheating or wear.

Note: Choose the right type of lubricant and adjust the lubrication frequency according to environmental conditions.

Tighten bolts: Due to long-term vibration of the equipment, the bolts may loosen and should be tightened regularly to ensure structural stability.

2. Predictive maintenance

Use monitoring tools: such as vibration analyzers, thermal imagers and oil analysis equipment to detect the operating status of the equipment.

Data analysis: Through historical data and real-time monitoring, predict the failure point of the equipment and take measures in advance.

3. Fault maintenance

Quick response mechanism: After the equipment fails, timely organize maintenance to avoid the spread of the fault.

Spare parts management: The wearing parts and core components of key equipment need to be prepared in advance to shorten the maintenance time.

Maintenance focus of different types of equipment

1. Electrical equipment

Motor

Regularly clean the dust on the cooling fan and the casing to maintain good heat dissipation.

Check the insulation performance of the motor winding to prevent leakage or short circuit.

Distribution cabinet

Check whether the terminal is loose to prevent poor contact.

Test whether the cable insulation layer is intact to avoid leakage risk.

2. Mechanical equipment

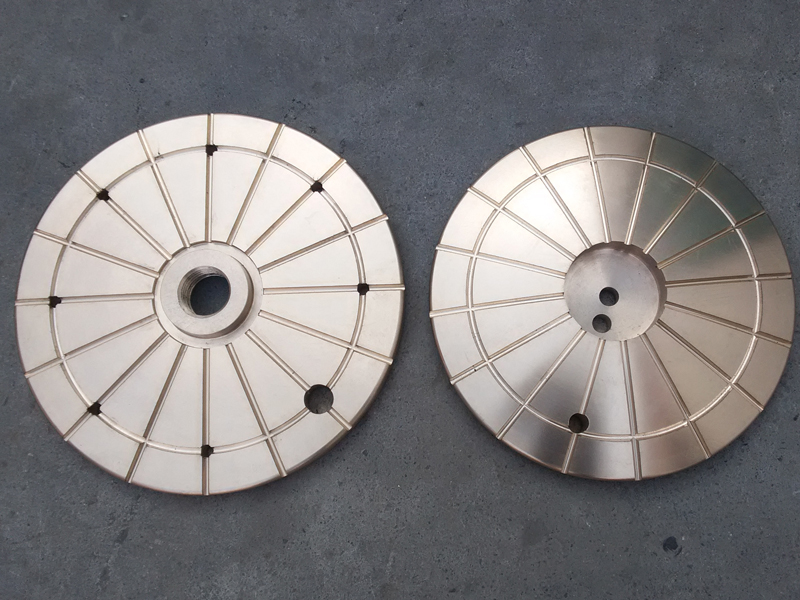

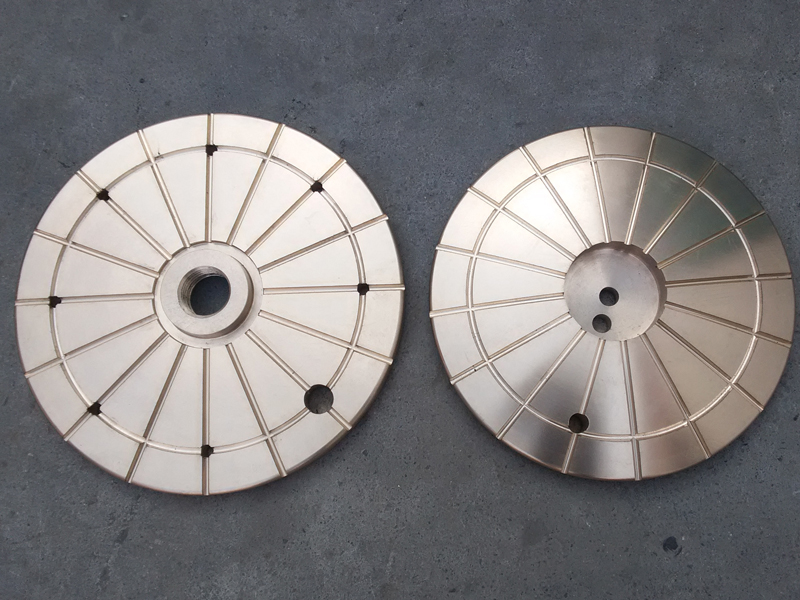

Crusher

Check whether there are foreign objects in the crushing chamber to prevent equipment damage.

Replace wearing parts such as linings and hammers regularly.

Belt conveyor

Adjust the belt tension to avoid slipping or over-tightening.

Check the wear of rollers, drums and other parts regularly, and replace aging parts in time.

3. Hydraulic equipment

Hydraulic system

Check the cleanliness of the hydraulic oil and replace the hydraulic oil if necessary.

Replace the hydraulic filter regularly to prevent impurities from clogging the pipeline.

Seals

Check whether the seals are aged or damaged to ensure that there is no leakage in the hydraulic system.

Management suggestions for maintenance of mine electromechanical equipment

Establish equipment files

Each equipment should have a detailed file to record the equipment model, service life, maintenance records and repair records.

Develop maintenance plans

Develop annual, quarterly and monthly maintenance plans based on the equipment's operating time and load conditions.

Train maintenance personnel

Organize professional training regularly to improve the technical level and troubleshooting capabilities of maintenance personnel.

Implement the responsibility system

Related Reading:

Brief Introduction to the Dynamic Pressure Lubrication Method of the Ball Mill Main Bearing Bushing

What are the applications of bronze bushings?

Applications and basic knowledge of bronze