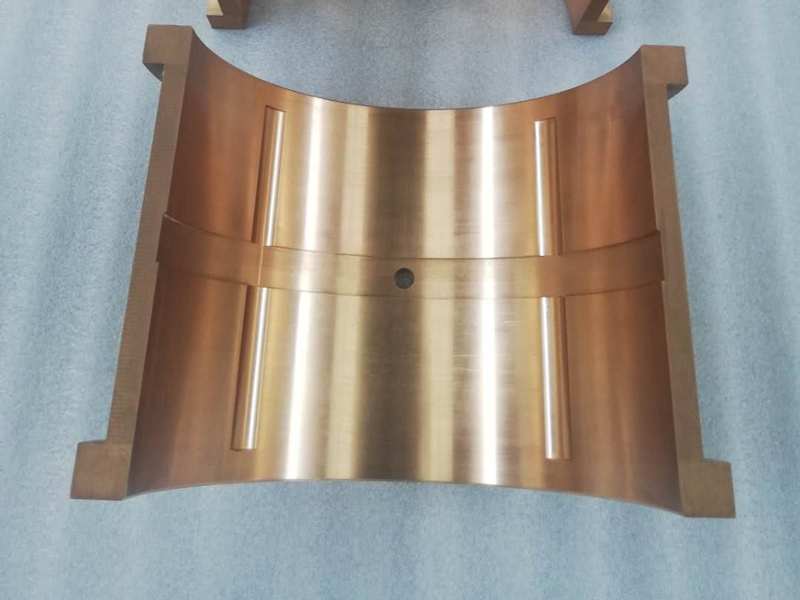

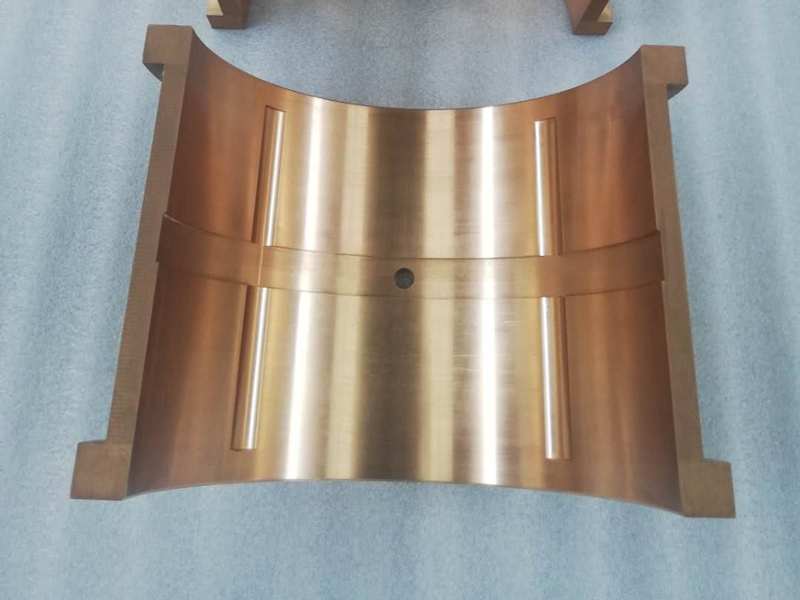

Copper bearing is an important component widely used in mechanical equipment. It is mainly used to carry the rotation of the shaft, reduce friction, provide lubrication and support. It is usually made of copper alloy (such as aluminum bronze, tin bronze, etc.), with good wear resistance, corrosion resistance and high load capacity. The structural characteristics of copper bearing mainly include the following aspects:

1. Material

Copper bearing is generally made of copper alloy, the common ones are:

Aluminum bronze: has good wear resistance, corrosion resistance and high temperature resistance, suitable for high load conditions.

Tin bronze: has good wear resistance, corrosion resistance and strong strength, suitable for medium and high load conditions.

Lead bronze: suitable for low speed, heavy load and large vibration occasions, because it has self-lubrication.

2. Wear-resistant layer and structural design

Copper bearing generally includes a multi-layer structure, usually with a higher hardness wear-resistant layer and a softer base layer:

Wear-resistant layer: This layer is usually composed of the copper alloy itself or a surface layer with other alloying elements, with strong wear resistance and corrosion resistance.

Matrix layer: The matrix of copper bearing is copper alloy, which has good plasticity and low friction coefficient.

3. Lubrication groove design

The surface of copper bearing is often designed with lubrication grooves (also called oil grooves or oil channels) for storing and distributing lubricating oil. The design of these grooves can effectively reduce friction, reduce temperature, and improve lubrication effect, extending the service life of bearing.

4. Anti-seizure design

The bearing is often designed with a certain "gap" to ensure that there is enough space during installation so that the lubricating oil can enter between the bearing and the shaft to form an oil film to prevent direct metal contact, thereby reducing wear and seizure.

5. Load-bearing capacity and elasticity

The material of copper bearing has good load-bearing capacity and can still maintain sufficient elasticity and durability when running under high load, which is especially important for the load of large-sized shafts.

6. Heat dissipation capacity

The copper material has good thermal conductivity, which helps the bearing to effectively dissipate heat and maintain a suitable temperature when running at high speed to prevent damage to the bearing due to overheating.

7. Corrosion resistance

Copper alloys have natural corrosion resistance, especially for mechanical parts used in water or chemical environments. Due to the chemical stability of copper, bearings can withstand harsh working environments.

8. Self-lubrication (under certain special designs)

Some copper alloy bearings are also designed to be self-lubricating, through special material formulations or the addition of tiny lubricating particles to achieve long-term lubrication effects and reduce dependence on external lubricants.

Summary

The structural characteristics of copper bearings are mainly reflected in their material (copper alloy), wear resistance, good lubricity, reasonable heat dissipation design and corrosion resistance. Through these designs, it can reduce friction, extend service life and provide stable operation in various industrial equipment.