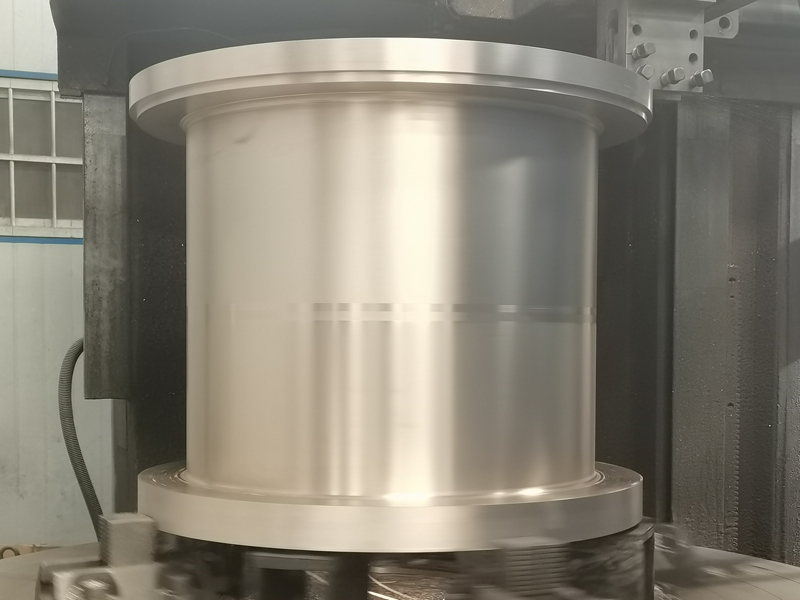

Bronze sealing rings are often used to provide sealing functions in industrial and mechanical applications. They are mainly used to prevent liquid or gas leakage and protect the internal parts of the equipment from external contamination. The specific role can be understood from the following aspects:

1. Prevent leakage: Bronze sealing rings are usually installed at mechanical connections. Through the compression between the mating surfaces, a sealing barrier is formed to prevent fluids (such as water, oil, gas, etc.) from leaking from the joints of the equipment.

2. High temperature resistance and corrosion resistance: Bronze alloys have good high temperature resistance and corrosion resistance. Therefore, bronze sealing rings can work for a long time at high temperatures or in harsh environments, and are especially suitable for sealing requirements under certain special working conditions.

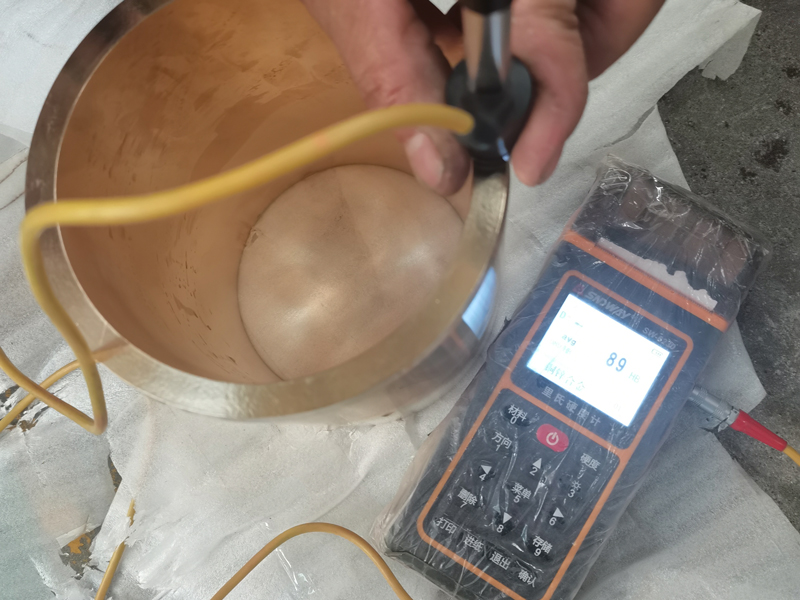

3. Wear resistance: Bronze materials have high wear resistance. The sealing ring can maintain a long service life during long-term use, effectively reduce wear, and avoid frequent replacement.

4. Strong adaptability: Bronze has good plasticity and elasticity, and can adapt to the unevenness of the contact surface to a certain extent to ensure the sealing effect.

5. Self-lubricating: Some types of bronze alloys have certain self-lubricating properties, which allows the sealing ring to reduce friction, reduce wear, and improve the sealing effect during movement or rotation.

Bronze sealing rings are widely used in valves, pumps, mechanical equipment, aerospace, ships and other fields, especially in environments that require pressure resistance, corrosion resistance and high temperature resistance, playing an important role.

Russian

Russian  Albanian

Albanian  Arabic

Arabic  Amharic

Amharic  Azerbaijani

Azerbaijani  Irish

Irish  Estonian

Estonian  Odia (Oriya)

Odia (Oriya)  Basque

Basque  Belarusian

Belarusian  Bulgarian

Bulgarian  Icelandic

Icelandic  Polish

Polish  Bosnian

Bosnian  Persian

Persian  Afrikaans

Afrikaans  Tatar

Tatar  Danish

Danish  German

German  French

French  Filipino

Filipino  Finnish

Finnish  Frisian

Frisian  Khmer

Khmer  Georgian

Georgian  Gujarati

Gujarati  Kazakh

Kazakh  Haitian Creole

Haitian Creole  Korean

Korean  Hausa

Hausa  Dutch

Dutch  Kyrgyz

Kyrgyz  Galician

Galician  Catalan

Catalan  Czech

Czech  Kannada

Kannada  Corsican

Corsican  Croatian

Croatian  Kurdish (Kurmanji)

Kurdish (Kurmanji)  Latin

Latin  Latvian

Latvian  Lao

Lao  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Kinyarwanda

Kinyarwanda  Romanian

Romanian  Malagasy

Malagasy  Maltese

Maltese  Marathi

Marathi  Malayalam

Malayalam  Malay

Malay  Macedonian

Macedonian  Maori

Maori  Mongolian

Mongolian  Bengali

Bengali  Myanmar (Burmese)

Myanmar (Burmese)  Hmong

Hmong  Xhosa

Xhosa  Zulu

Zulu  Nepali

Nepali  Norwegian

Norwegian  Punjabi

Punjabi  Portuguese

Portuguese  Pashto

Pashto  Chichewa

Chichewa  Japanese

Japanese  Swedish

Swedish  Samoan

Samoan  Serbian

Serbian  Sesotho

Sesotho  Sinhala

Sinhala  Esperanto

Esperanto  Slovak

Slovak  Slovenian

Slovenian  Swahili

Swahili  Scots Gaelic

Scots Gaelic  Cebuano

Cebuano  Somali

Somali  Tajik

Tajik  Telugu

Telugu  Tamil

Tamil  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Welsh

Welsh  Uyghur

Uyghur  Urdu

Urdu  Ukrainian

Ukrainian  Uzbek

Uzbek  Spanish

Spanish  Hebrew

Hebrew  Greek

Greek  Hawaiian

Hawaiian  Sindhi

Sindhi  Hungarian

Hungarian  Shona

Shona  Armenian

Armenian  Igbo

Igbo  Italian

Italian  Yiddish

Yiddish  Hindi

Hindi  Sundanese

Sundanese  Indonesian

Indonesian  Javanese

Javanese  Yoruba

Yoruba  Vietnamese

Vietnamese  Hebrew

Hebrew